PWM (Pulse Width Modulation) is one of the most fundamental techniques in automation and motion control. It allows precise control of voltage and power delivery without wasting energy, making it ideal for systems that require smooth and efficient operation — from motor drives to LED lighting and HVAC control. In this article, Flextech explains how PWM works, its role in modern automation systems, and what to keep in mind when applying PWM to your business operations.

What is Pulse Width Modulation?

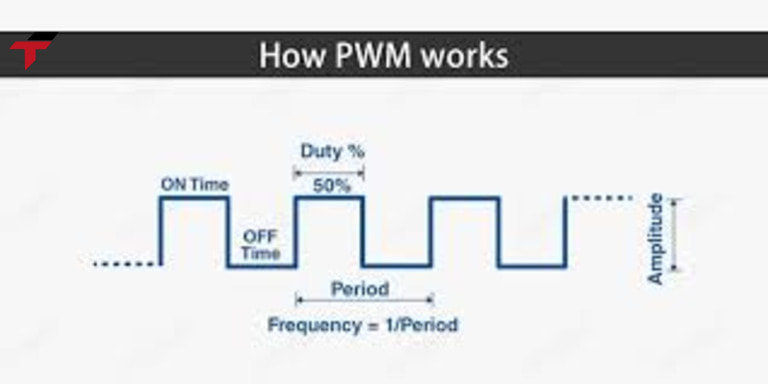

PWM (Pulse Width Modulation) is a signal control technique that regulates the effective output voltage by adjusting the width of each pulse within a fixed period. Even though the voltage is switched between ON and OFF states, changing the duty cycle (the ratio of ON time to total cycle time) allows fine-tuning of the average power delivered to the load.

This method is highly energy-efficient and enables smooth control without the need for variable resistors or complex analog circuits. For example:

- A 25% duty cycle provides low output power (the device is ON 25% of the time).

- A 75% duty cycle provides high output power (the device is ON most of the time).

PWM is thus the foundation for adjusting motor speed, LED brightness, or heater temperature with minimal power loss.

What is the operating principle of PWM?

PWM operates based on a square pulse signal that is repeated in cycles. In each cycle, the signal is on (ON) for a certain period of time and then off (OFF) for the rest. The on-time ratio in a cycle is called the duty cycle, measured in percentage (%).

For example:

- Duty cycle 25%: on 25% of the time, off 75%

- Duty cycle 50%: on and off are equal

- Duty cycle 75%: on 75%, off 25%

Although the signal is only at two high/low levels, the average output voltage will change corresponding to the duty cycle. This allows the power supplied to the load (such as motor, LED…) to be adjusted smoothly and save energy, without constantly changing the voltage.

PWM operates based on a square pulse signal that is repeated in cycles

What is PWM and its relationship with the Servo system?

In motion control, PWM is the primary signal used to control analog and digital servos. It defines the servo’s rotation angle, speed, or torque based on the pulse width received from the controller (PLC, Arduino, or microcontroller).

In closed-loop servo systems, PWM works in coordination with feedback from encoders to maintain accuracy and stability. In short, PWM acts as the communication bridge between the controller and the actuator, ensuring synchronized, precise, and efficient operation.

What benefits does PWM bring to businesses?

PWM (Pulse Width Modulation) offers multiple advantages that directly enhance energy efficiency, control precision, and system reliability in industrial automation. Below are key benefits businesses can gain from implementing PWM technology:

- Energy Saving and Cost Efficiency: Regulates power by switching signals ON/OFF rapidly instead of adjusting continuous voltage. Reduces heat loss in power components such as transistors and drivers. Lowers electricity consumption, especially in variable load systems like fans, pumps, and conveyors.

- Precise and Stable Control: Adjusts output smoothly through duty cycle changes, allowing accurate control of motor speed, torque, or LED brightness. Ensures smooth operation without flickering or jerky motion in actuators. Improves product consistency and process accuracy in automated production lines.

Easy Integration with Control Systems: Supported by most microcontrollers and PLCs (Arduino, STM32, Raspberry Pi, etc.). Enables flexible system scaling and fast deployment in both simple and industrial control systems. - Wide Application Range: Used in controlling DC motors, servo drives, and stepper motors. Applied in LED dimming, fan speed adjustment, pump control, and HVAC systems. Integrated in power converters and inverters for efficient power management.

- High Signal Stability and Noise Resistance: Digital ON/OFF nature minimizes electromagnetic interference (EMI) compared to analog signals. Maintains stable communication even in harsh industrial environments.

Benefits does PWM bring to businesses

What are the notes when designing a PWM circuit?

Although PWM is a popular and effective control method, designing a PWM circuit requires careful consideration to ensure a stable signal and a durable circuit:

- Choosing the right frequency for the load: The PWM frequency should be selected according to the type of load: With a DC motor 10–20kHz helps reduce noise and improve performance. With LEDs ≥1kHz to avoid flickering. Choosing the wrong frequency can cause vibration, noise or reduce the life of components.

- Handling signal noise in industrial environments: PWM signals are susceptible to electromagnetic interference (EMI), especially when transmitted over long wires or near high-power devices. Solutions include using twisted pair cables or shielded cables, adding filter capacitors, inductors, separating the control signal lines and power sources

- Protect the power circuit when switching on/off quickly: Continuous switching can generate high voltage pulses that damage MOSFETs, IGBTs or loads. It is necessary to attach a flyback diode to the inductive load, use a snubber circuit to suppress the pulse, add a fuse or overcurrent protection circuit.

Pulse Width Modulation is commonly used in which fields?

PWM is a core technology in industrial control systems thanks to its ability to adjust output power efficiently without causing large energy losses. Here are some typical applications:

- Controlling servo motors and DC motors: PWM allows precise adjustment of motor speed, position or torque – an essential element in production lines, industrial robots, packaging machines, etc.

- Adjusting LED brightness and temperature: In industrial lighting systems or heaters, PWM is used to control the brightness of LED lights or the heat dissipation capacity of heating resistors.

- Controlling fans, pumps and HVAC systems: PWM helps adjust the speed of cooling fans, liquid pumps, or air conditioning ventilation systems (HVAC) to optimize performance and save energy.

- Integration with microcontrollers, Arduino, PLC: PWM is an easy-to-implement control method, supported in most popular microcontroller lines such as Arduino, STM32, Raspberry Pi, and expansion modules of industrial PLCs.

Pulse Width Modulation is commonly used in which fields

Conclusion

PWM (Pulse Width Modulation) plays a vital role in automation, bridging simplicity and precision in power control. By understanding how PWM works — and how to apply it effectively — businesses can improve system performance, enhance energy efficiency, and extend equipment lifespan.

With Flextech’s expertise in automation integration and motion control, we can help you design and implement PWM-based systems tailored to your production needs — ensuring stable, efficient, and future-ready operations.