Acceleration Feedforward (AFF) is a powerful control strategy in modern servo systems that improves response speed, enhances motion smoothness, and minimizes position errors. By predicting and compensating for acceleration forces, AFF helps engineers optimize high-speed, high-load, or precision-critical automation applications, ensuring reliable and efficient operation.

What is Acceleration Feedforward?

Acceleration Feedforward (AFF) is an advanced control technique used in servo systems to predict and offset inertia-related forces during acceleration or deceleration.

Unlike traditional feedback-based control, which reacts after detecting an error, AFF proactively generates the required torque at the start of motion based on the expected acceleration profile. This allows the motor to move more responsively and smoothly — minimizing lag, overshoot, and vibration.

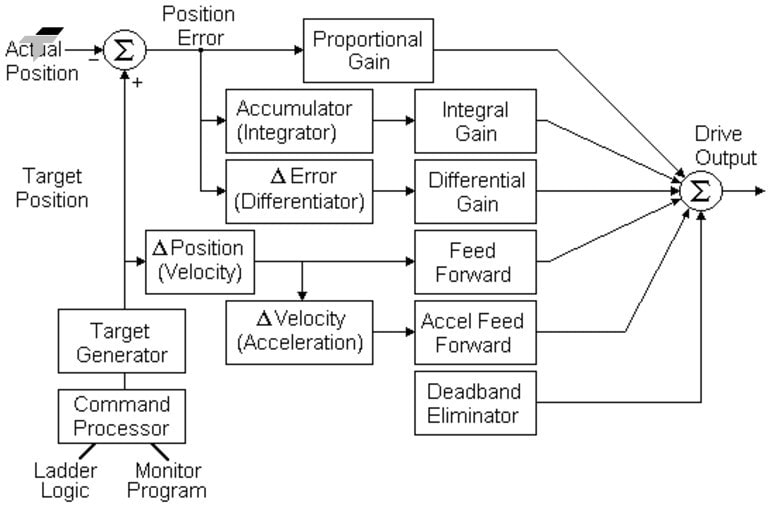

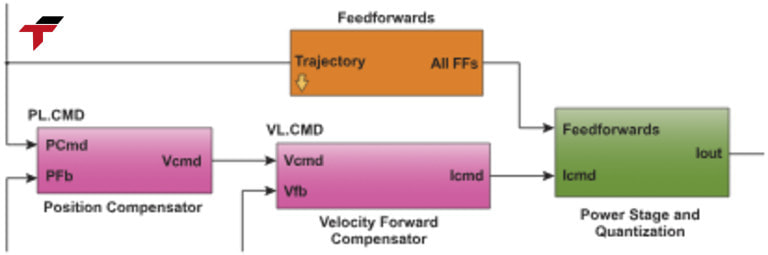

How does Acceleration Feedforward relate to the Servo System?

Acceleration Feedforward (AFF) is part of the control algorithm of the servo system – the system that precisely controls the position, speed and torque of the motor.

In a standard servo system, the control loop usually consists of:

- Position Loop

- Velocity Loop

- Current Loop

However, when relying solely on feedback to correct errors, the system may experience delays, slight oscillations, or deviations from the initial position, especially when the load is heavy or moving quickly.

At this point, Acceleration Feedforward is introduced as a control branch in parallel with the feedback loops, to compensate the torque directly based on the preset acceleration signal.

Acceleration Feedforward (AFF) is part of the control algorithm of the servo system

When to use Acceleration Feedforward?

Acceleration Feedforward (AFF) is one of the advanced tuning tools that helps improve the performance of servo systems – especially in situations that require fast response, precise motion and effective load control.

Not all systems require AFF, but in the following cases, enabling and optimizing this function will make a noticeable difference in the quality of motion and system stability.

- When the system is heavily loaded, high inertia: In machines with heavy slides, long shafts or large rotating mechanisms, inertia forces will cause the motor to respond slowly when starting to move.

- When fast movement, precise stopping: AFF is useful in high-speed applications such as pick & place robots, filling, or fast packaging – where the motor must accelerate and stop quickly in a short time.

- When position deviation occurs at start: A common situation is that the motor shaft “kicks back” or “lags slightly” when starting to run – because the PID feedback does not have time to process. AFF compensates force before errors occur, helping the motor to start moving smoothly and accurately, limiting the phenomenon of early travel delay.

- When the system fluctuates during the acceleration/deceleration phase: If the system vibrates slightly or makes a “groaning” sound when accelerating or stopping, it may be due to a lack of compensation force suitable for the required acceleration.

At that time, AFF plays a role in supplementing the necessary force at the right time, helping to reduce mechanical vibration and increase the life of the equipment.

Acceleration Feedforward (AFF) is one of the advanced tuning tools that helps improve the performance of servo systems

What are the benefits of Acceleration Feedforward for businesses?

After understanding the role and operation of Acceleration Feedforward in servo systems, the question arises: What specific value does the addition of this algorithm bring to the motion control process? Below are the outstanding benefits that AFF brings to both design engineers and actual operators.

- Increased response when accelerating/decelerating: AFF helps the motor react faster to sudden changes in speed, especially during the starting or stopping phase. This helps the servo system follow the control trajectory more closely, without delaying the command.

- Reduce position error when starting movement: Instead of waiting for errors to appear and then adjusting (feedback), AFF proactively compensates force from the beginning. Thanks to that, the motor reaches the target position faster and more accurately, limiting deviation from the origin point.

- Increased smoothness of operation: The addition of appropriate torque during the acceleration phase results in smooth, stable motion – especially important for applications requiring high precision and low mechanical vibration.

- Reduced vibration, limited mechanical wear: Thanks to better control of acceleration, the system operates smoothly, reducing shock loads and limiting shock – thereby extending the life of the actuator and reducing maintenance costs.

Benefits of Acceleration Feedforward for businesses

Conclusion

Acceleration Feedforward is an essential element in modern servo control, enabling motors to respond faster, move more smoothly, and maintain precise positioning by anticipating and compensating for acceleration-related forces.

In high-speed, high-load, and precision-critical automation environments, effectively configuring AFF not only enhances system performance but also reduces mechanical stress, lowers error rates, and extends the lifespan of the equipment. Proper use of this control strategy ensures reliable operation, minimizes downtime, and maximizes efficiency in demanding industrial applications.

At Flextech, we provide expert guidance and solutions for integrating Acceleration Feedforward into your servo systems, helping businesses optimize motion control, improve production quality, and achieve maximum operational efficiency.