Ambient temperature is a critical environmental factor that can significantly influence the performance, reliability, and lifespan of servo motors, drivers, and associated control devices. In industrial automation, understanding how ambient temperature interacts with servo systems allows engineers to design safer, more efficient, and more durable solutions. By proactively monitoring and controlling temperature, businesses can ensure stable operations, minimize downtime, and reduce maintenance costs across production lines.

What is Ambient Temperature?

Ambient temperature refers to the temperature of the surrounding air in which a device operates, excluding heat generated by the device itself. It differs from core or surface temperature, which measure the internal or surface heat of the equipment. Ambient temperature reflects the environmental conditions that affect heat dissipation, component longevity, and system stability.

In servo systems, manufacturers often specify an ideal operating range, typically between 0°C and 40°C. Operating outside this range can lead to reduced motor output, thermal protection activation, or accelerated aging of components such as capacitors, power modules, and bearings.

What is the relationship between Ambient Temperature and Servo System?

Ambient temperature has a direct and measurable impact on servo system performance:

- Overheating: If ambient temperature is high, heat dissipation becomes less efficient, leading to rapid motor and driver temperature increases. This can reduce torque and trigger protection mechanisms.

- Reduced component life: Prolonged exposure to high temperatures accelerates wear and reduces the lifespan of key components.

- Position accuracy issues: Thermal expansion in mechanical components and interference with encoders can cause errors in position control.

- Low-temperature effects: Environments that are too cold, such as cold storage or outdoor installations in winter, can result in condensation, frost, or encoder slippage, potentially causing short circuits or inaccurate readings.

- Operational instability: Extreme temperatures may affect driver response times, causing vibrations, overshoot, or unstable movement.

To mitigate these effects, engineers should:

- Continuously monitor ambient temperature in the installation area.

- Provide adequate ventilation, cooling fans, or air conditioning for drivers, motors, and electrical cabinets.

- Select servo equipment rated for the specific operating environment, whether hot, humid, dusty, or exposed to outdoor conditions.

Ambient temperature has a direct and measurable impact on servo system performance

What are the benefits of controlling Ambient Temperature?

Proper management of ambient temperature provides a wide range of benefits in industrial automation and servo system applications, directly affecting system reliability, efficiency, and overall operational performance:

- Consistent performance: By maintaining the ambient temperature within the recommended range, servo motors and drivers can consistently deliver their rated torque, speed, and responsiveness. This ensures that production lines operate smoothly without unexpected performance fluctuations caused by thermal stress or overheating.

- Extended equipment life: Excessive heat is one of the leading causes of premature component failure. Proper temperature control reduces thermal stress on key internal parts such as capacitors, coils, power modules, and bearings.

- Minimized downtime: Servo systems operating in a stable ambient temperature are less likely to trigger thermal protection mechanisms that can stop or slow down equipment.

- High control accuracy: Feedback devices like encoders and sensors are highly sensitive to temperature fluctuations. Maintaining optimal ambient temperature prevents drift or signal delays, ensuring precise position, speed, and torque control.

- Lower maintenance and operational costs: Equipment that runs in a suitable temperature environment experiences less mechanical and electrical stress. Reduced wear and tear means fewer repairs, lower spare-part costs, and less frequent maintenance schedules, freeing engineering teams to focus on other tasks.

- Energy efficiency: When motors and drivers are not stressed by thermal extremes, they operate more efficiently. Maintaining a proper ambient temperature reduces the need for overcompensation – such as higher current or power adjustments to achieve desired performance, saving energy and lowering operational costs.

Benefits of controlling Ambient Temperature

What are the risks when Ambient Temperature exceeds the allowable threshold?

Exceeding the recommended ambient temperature range (commonly above 40°C for standard servo systems) introduces several critical risks that can negatively affect performance, safety, and long-term reliability:

- Position instability and motion errors: High ambient temperatures reduce the ability of servo motors to dissipate heat efficiently, which can cause motors to overshoot, oscillate, or fail to hold precise positions during low-speed operations. Even small temperature deviations can significantly affect high-precision tasks.

- Accelerated component degradation: Thermal stress accelerates aging of key electronic and mechanical components, including capacitors, power modules, sensors, and motor windings. Continuous operation in high heat can drastically shorten component lifespan and increase the likelihood of unexpected system failures.

- Automatic derating or shutdown: Most modern servo drivers are equipped with thermal protection features. If ambient temperatures exceed safe thresholds, drivers may automatically reduce torque output or shut down entirely to prevent damage.

- Feedback inaccuracies and control errors: High temperatures can affect encoders, resolvers, and other feedback devices, causing delayed signals or erroneous readings. This can result in cumulative position errors, misalignment, and incorrect speed or torque control, compromising the precision of the system.

This condition not only affects machine performance but can also lead to system failure if not handled promptly.

What to note when choosing a servo for a high/low temperature environment?

When the servo device is installed in an environment with abnormal Ambient Temperature (too hot or too cold), the engineer needs to consider the following important factors:

- Choose a servo motor and driver with a suitable temperature range: Check the manufacturer’s specifications. For harsh environments, it is recommended to choose a type with a wider operating range than the standard (eg: -10°C ~ 50°C).

- Prioritize devices with good heat dissipation: Choose a motor with an aluminum heat sink, a driver with ventilation slots or additional fan support.

- Consider the derating factor: In high temperature environments, some devices may reduce capacity. It is necessary to calculate excess load when choosing a model to avoid lack of torque in actual operation.

- Protection and anti-humidity/frost: With low temperatures (cold storage, highlands, etc.), it is necessary to pay attention to the risk of condensation causing short circuits. It is recommended to use an additional sealed electrical cabinet with heat drying or dehumidification.

- Consider IP protection standards: When installed in hot dusty environments or near heat sources (furnaces, furnace lines), it is recommended to choose equipment with high IP standards (IP54 or higher) to increase durability.

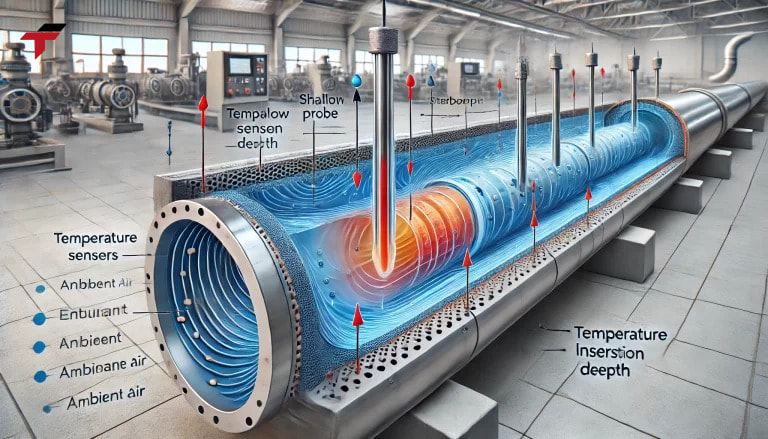

- Equip with a temperature sensor and early warning: Add a temperature sensor in the electrical cabinet or on the motor to monitor Ambient Temperature and activate a warning if it exceeds the safety threshold.

Note when choosing a servo for a high/low temperature environment

Conclusion

Ambient Temperature may appear to be a simple environmental factor, but it plays a critical role in the performance, stability, and durability of servo motors and drivers in motion control systems. Understanding how temperature affects each component allows engineers to select the right equipment, design proper ventilation or cooling solutions, and ensure long-term operational reliability.

In harsh industrial environments such as areas with high heat, humidity, or extreme cold, actively monitoring and controlling ambient temperature is essential. Proper temperature management helps maintain precise motion control, reduces mechanical wear, and minimizes unexpected downtime, supporting smoother and more reliable production processes.

At Flextech, we provide comprehensive servo solutions—including motors, drivers, and controllers—paired with expert guidance on installation and environmental considerations. Our technical team can advise on selecting devices suited for challenging ambient conditions, helping businesses achieve maximum efficiency, safety, and longevity in their automation systems.