Capacitive Coupling is a key factor affecting signal integrity in high-precision servo systems. Flextech explains how this phenomenon occurs, its impact on servo accuracy, and practical strategies to prevent interference, ensuring reliable and efficient motion control.

What is Capacitive Coupling?

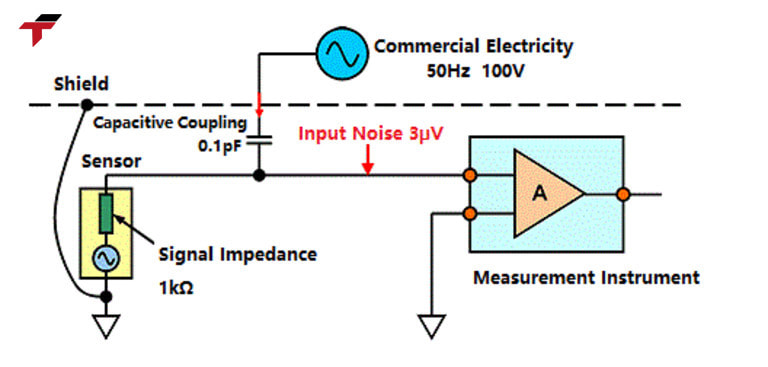

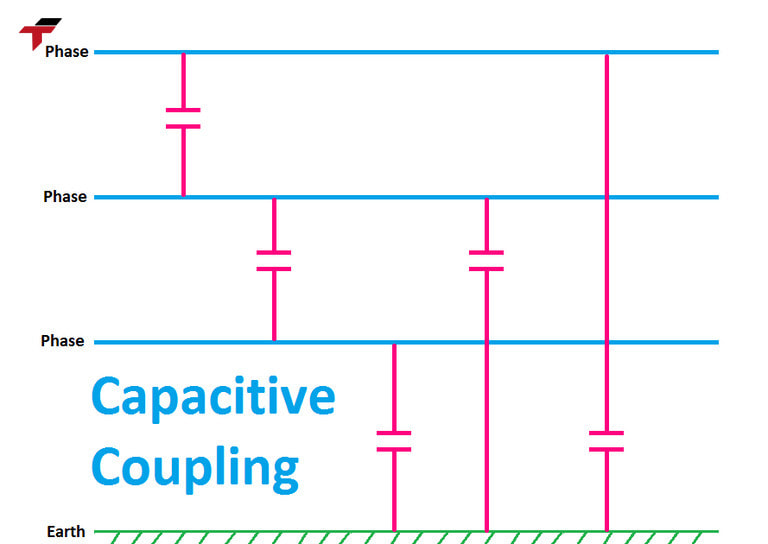

Capacitive Coupling occurs when an electrical signal is transferred between two conductors without direct physical contact, via the electric field formed between them. In industrial automation, this often happens when power cables run too close to signal or encoder wires. The resulting interference can induce unwanted currents in the signal lines, potentially leading to inaccurate readings or control errors.

In servo motor systems, this is particularly critical because motor power lines are high-current paths, and the encoder or feedback cables carry low-level signals. Even small induced voltages can create errors in position or speed feedback, disrupt communication between the driver and PLC, and trigger false alarms.

How does Capacitive Coupling affect the servo system?

Capacitive Coupling is a frequent cause of signal noise in servo systems. Its effects, if not mitigated, can compromise the performance and safety of motion control applications:

- Distorted control and feedback signals: The interference can corrupt encoder readings, causing the driver to move the motor incorrectly.

- Reduced loop accuracy: Noise in position, velocity, or torque loops can introduce oscillations, overshoot, or jerky motion.

- False alarms from the driver: High-frequency coupling can trigger overcurrent, encoder errors, or phase loss warnings, leading to unexpected stops.

- Vibrations or slight movements at low speed: Misinterpreted signals may result in unintended micro-movements or temporary halts.

- Long-term stability issues: Persistent interference may degrade ICs, capacitors, and sensors over time, reducing the overall lifespan of the system.

Even if subtle, these effects cumulatively decrease precision, reliability, and the operational lifespan of the servo system.

Capacitive Coupling is a frequent cause of signal noise in servo systems

What are the benefits of Capacitive Coupling?

Capacitive coupling provides several practical advantages when applied correctly in servo and industrial control systems:

- Signal isolation without physical connection: Enables signals to transfer safely between circuits without direct contact, protecting sensitive components from DC offsets and voltage spikes.

- Efficient high-frequency AC signal transmission: Ensures accurate signal propagation at high frequencies, reducing distortion and maintaining precise servo responses.

- Noise reduction in amplifier and control circuits: Filters unwanted oscillations and interference, stabilizing feedback and control loops for smoother operation.

- Supports non-contact sensing applications: Forms the foundation of capacitive sensors, ideal for detecting objects in clean or harsh environments without mechanical wear.

- Enhanced safety in sensitive or explosive environments: Eliminates sparks or arcing, making it suitable for chemical, petrochemical, and mining automation systems.

- Improved system reliability and efficiency: Helps maintain consistent signal quality, reduces the need for additional amplification, and allows compact, flexible system designs.

Overall, capacitive coupling not only provides safe and efficient signal transmission but also contributes to system stability, accuracy, and long-term durability in modern servo applications.

Capacitive coupling provides several practical advantages when applied correctly in servo and industrial control systems

Disadvantages of Capacitive Coupling in Servo Systems

Despite its practical applications in the electronics industry, Capacitive Coupling often causes serious problems in precision control environments such as servo systems. Here are some typical disadvantages to note:

- Causes feedback and control signal distortion: When coupling occurs between the signal line and the power line, unwanted electric fields can distort the signal, causing control errors.

- Increased risk of cross-talk: Especially when signal cables run close together in a narrow space, capacitive coupling can cause one signal to “contaminate” another signal → difficult to detect, easy to miss when checking for errors.

- Causes false error alarms from the driver: Capacitive noise can trigger false alarms from the controller, causing unexpected machine stops and interrupting production.

- Reduced system performance and stability: In position and speed feedback loops, noise signals can cause the servo to oscillate slightly, respond unstablely, or lose positioning accuracy.

- Long-term impact on component life: Prolonged noise causes the control ICs, filter capacitors, or encoders to heat up, thereby reducing the durability of the entire servo system.

Disadvantages of Capacitive Coupling in Servo Systems

How to prevent noise caused by Capacitive Coupling?

To limit the negative effects of capacitive coupling in the servo system, engineers need to pay attention right from the design stage of the electrical system and installation of the wiring. Some effective solutions include:

- Isolating signal wires and power wires: Absolutely do not run encoder, feedback or PLC signal wires in parallel with the motor power supply wire. Prioritize separate wiring in separate grooves/channels.

- Use shielded cables: Signal wires should be made of copper mesh or foil to prevent interference, and ground one end according to the manufacturer’s instructions.

- Install noise filters (ferrite core, EMI filter): Install at the driver or PLC input to reduce high-frequency noise currents transmitted back into the system.

- Increase the distance between the AC power cord and signal wire: Every centimeter of distance helps significantly reduce the capacitance formed between the two wires.

- Grounding the system properly: Ensure that the entire electrical cabinet frame, equipment enclosure and shielded wire all have a common ground point, avoiding creating a mass loop that causes reverse interference.

Conclusion

Capacitive Coupling is more than just a physical effect in modern servo systems—it plays a critical role in the accuracy, stability, and overall performance of motion control operations. By understanding how capacitive coupling occurs, recognizing its benefits and potential risks, and implementing effective mitigation strategies, engineers can design systems that operate reliably, precisely, and safely.

In industrial environments where precision and continuity are essential, controlling capacitive interference is not optional—it is a vital part of system design and maintenance. At Flextech, we provide expert guidance and practical solutions to minimize capacitive coupling effects, helping businesses deploy high-performance servo systems with optimal stability, extended equipment life, and minimal operational errors.