Cycle Time is a crucial metric in manufacturing that measures the time to produce a unit or complete a production cycle. Understanding its calculation, influencing factors, and optimization strategies helps businesses improve efficiency, reduce costs, and maintain product quality. This guide by Flextech explains everything you need to know about Cycle Time and how to use it to boost manufacturing productivity.

What Is Cycle Time in Modern Manufacturing?

Cycle Time is a fundamental metric in the manufacturing and automation sectors. It refers to the total time required to complete one production cycle or to produce a single unit of product. This metric is crucial for assessing operational efficiency, productivity, and overall manufacturing performance.

At Flextech, we integrate Cycle Time analysis with ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems) to ensure accurate production planning and real-time monitoring of manufacturing lines. A shorter Cycle Time generally translates into higher productivity and faster response to market demand.

How Can We Measure Cycle Time Accurately?

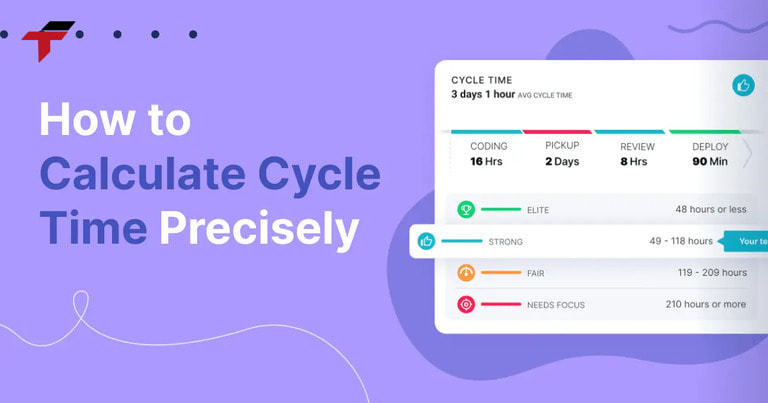

Cycle Time is the average time required to complete a unit of product or a task in the production line. To calculate cycle time, you can use the following formula:

Cycle Time = Net Production Time / Number of units produced

- Net Production Time: This is the actual time spent on production, excluding downtime, rest or other interruptions.

- Number of units produced: The total number of products completed during the net production time.

Illustrative example:

A manufacturing plant operates for 6 hours per day (360 minutes), but only 300 minutes are actual production time, the rest is spent on machine maintenance and other interruptions. During this time, the plant produces 150 products.

Cycle time = 300 minutes/150 units = 2 minutes/unit

This means that on average, it takes the factory 2 minutes to produce one unit.

Cycle Time = Net Production Time / Number of units produced

What factors affect the calculation of Cycle Time?

Cycle Time is not a fixed number; it is influenced by multiple factors within the production process. Understanding these factors allows businesses to identify weaknesses, optimize workflows, and improve overall efficiency. Here are 6 key elements that affect Cycle Time:

Processing Time

Processing time is the actual time a product or task is handled by a machine or employee. Shorter processing times directly contribute to lower Cycle Time.

Example: A robot on an assembly line takes 30 seconds to attach a component to a product. Well-maintained and calibrated equipment ensures consistent processing time, boosting productivity.

Waiting Time

Waiting time refers to periods when a product is idle between stages due to bottlenecks, lack of materials, or errors in the production line. While non-value-added, waiting time significantly impacts overall Cycle Time.

Example: A product finishes stage A but must wait 10 minutes before moving to stage B because the machine at stage B is still busy processing another unit. Reducing waiting time through workflow optimization can dramatically improve Cycle Time.

Changeover Time

Changeover time is the time required to reset a machine or production line when switching from one product type to another or changing tools/molds. Long changeovers can halt the entire production line.

Example: A packaging line stops for 15 minutes to adjust for a different box size. Implementing SMED (Single Minute Exchange of Die) techniques can significantly reduce this downtime.

Raw material shortages

Delays or shortages in raw materials can increase waiting time and slow down processing speeds.

Example: Late delivery of materials forces the machine to pause, causing products to remain unfinished and increasing total Cycle Time. Effective inventory planning and quality control can minimize these disruptions.

Employee expertise

Workers who are inexperienced or unfamiliar with workflows may perform tasks slower, resulting in delays.

Example: A new operator takes longer to complete tasks compared to a trained, experienced worker. Regular training and clear standard operating procedures (SOPs) help reduce variations in Cycle Time.

External factors

Unexpected events such as power outages, software errors, or sudden changes in production schedules can also affect Cycle Time.

Example: A critical machine breakdown or ERP system failure can halt the production line. Investing in preventive maintenance and backup systems can mitigate the impact of these factors.

Identifying and optimizing each of these factors can not only shorten cycle times but also improve the efficiency of the entire manufacturing process. By understanding the factors that influence them, businesses can develop appropriate strategies to improve productivity, reduce costs and increase competitiveness in the market.

6 key elements that affect Cycle Time

Why Is It Important to Track Cycle Time?

Tracking Cycle Time is a critical practice in modern manufacturing, providing insights into efficiency, productivity, and overall operational performance. Monitoring this metric allows businesses to make informed decisions and improve both short-term operations and long-term strategy. 5 key benefits include:

- Enhancing Production Capacity: Shorter Cycle Times allow more products to be produced in the same timeframe, helping meet market demand and reduce delivery lead times.

- Measuring and Improving Performance: Cycle Time provides a benchmark to compare actual productivity against maximum production capacity, helping identify performance gaps and set improvement targets.

- Identifying Areas for Improvement: Analyzing Cycle Time reveals bottlenecks, delays, and inefficiencies in the production process, enabling process optimization and reduced lead times.

- Maintaining Product Quality: Consistently controlled Cycle Time ensures production steps are performed efficiently without compromising quality, improving product consistency.

- Evaluating Operational Efficiency: Long or fluctuating Cycle Times indicate performance issues, allowing businesses to detect inefficiencies and adjust operations promptly.

Cycle Time is not only an indicator of time, but also an overall measure of a business’s performance, productivity, and competitiveness. In the automation industry, optimizing Cycle Time is a vital factor to improve efficiency, reduce costs and quickly respond to market needs.

5 key benefits when Track Cycle Time

What is the difference between Cycle Time and Lead Time?

In manufacturing and automation management, Cycle Time and Lead Time are two important terms, but they are often confused because they both relate to the time in the manufacturing process. Here is a comparison chart of the differences between the 2 concepts:

| Cycle Time | Lead Time | |

| Definition | The time required to complete a single unit or a specific production step | The total time from when a customer places an order until the product is delivered |

| Scope | Focuses on value-added activities only; excludes waiting time and shipping | Includes all time, such as waiting, non-value-added activities, and delivery time |

| Purpose | Used to optimize production processes, measure performance, and improve efficiency | Used to manage customer expectations, track order fulfillment, and optimize the entire supply chain |

| Measurement Focus | Production speed and efficiency per unit | Overall delivery performance from start to finish |

| Implication for Business | Helps identify bottlenecks and improve workflow within manufacturing | Helps plan inventory, manage lead times, and enhance customer satisfaction |

How Does Automation Affect Cycle Time?

Automation significantly influences Cycle Time by streamlining processes, reducing manual intervention, and improving overall production consistency. Its impact can be seen across multiple dimensions:

- Faster Processing Speed: Automated machines and robotic systems can perform repetitive or precise tasks much faster than humans, reducing the time needed per unit.

- Reduced Waiting Time Between Stages: Automation can synchronize production steps, enabling continuous flow and minimizing idle time between processes.

- Consistency and Reliability: Machines execute tasks uniformly, decreasing variability caused by human error, fatigue, or skill differences. This reduces the need for rework, which can otherwise increase Cycle Time.

- Enhanced Flexibility: Advanced automated systems can quickly adapt to changes in product type, size, or production schedule, optimizing workflow without prolonged downtime.

- Continuous Operation: Unlike human operators, automated systems can run around the clock, maintaining steady output and shorter Cycle Times even during extended shifts.

- Data Integration and Monitoring: Automation often comes with sensors and software for real-time tracking. This allows managers to monitor Cycle Time accurately, detect inefficiencies immediately, and implement improvements proactively.

In summary, automation not only accelerates production but also increases predictability, efficiency, and quality, making it a critical factor in reducing Cycle Time in modern manufacturing environments.

Automation significantly influences Cycle Time by streamlining processes

What Are the Common Mistakes When Measuring Cycle Time?

Measuring Cycle Time accurately is essential for process optimization, but errors are common. Understanding these pitfalls helps ensure reliable data and meaningful insights:

- Including Non-Value-Added Time: Some businesses mistakenly include downtime, waiting periods, or breaks in Cycle Time measurement. This inflates the metric and masks the true efficiency of production.

- Overlooking Changeover and Setup Time: Failing to account for the time required to switch between products, tools, or molds can underestimate the actual production effort needed.

- Inconsistent Measurement Methods: Using different timing approaches across machines, shifts, or product lines leads to incomparable results and unreliable benchmarking.

- Ignoring Variability in Production: Not considering differences in operator speed, machine performance, or material flow can distort Cycle Time averages. Averages without context may hide significant delays in specific stages.

- Lack of Real-Time Data Tracking: Relying solely on manual observation or periodic sampling can miss short-term disruptions or inefficiencies that cumulatively affect Cycle Time.

- Failing to Analyze Root Causes: Simply recording Cycle Time without investigating why delays occur prevents meaningful process improvement and operational optimization.

Avoiding these mistakes allows businesses to obtain accurate Cycle Time data, identify bottlenecks, and implement targeted improvements, ultimately enhancing productivity, reducing costs, and improving competitiveness.

Common Mistakes When Measuring Cycle Time

Why Choose Flextech for Your Manufacturing and Automation Needs?

Flextech offers a comprehensive suite of services designed to optimize manufacturing efficiency, improve productivity, and enhance competitiveness. Here are 4 key reasons to choose Flextech:

- Advanced Technology: We leverage robotics, IoT, and smart systems for precise, reliable, and efficient production.

- Tailored Solutions: Our services are customized to meet your specific production needs and goals.

- Cost and Efficiency Focus: We streamline processes to increase throughput and lower operational costs.

- Full Support: From installation to training, we ensure your team can operate systems effectively.

Partnering with Flextech means boosting efficiency, maintaining quality, and staying competitive in today’s manufacturing landscape.