The industrial landscape in Malaysia, driven by the ambitious Industry 4.0 framework, demands machines that can deliver speed, precision, and reliability. At the heart of this advanced manufacturing lies a foundational component essential for sophisticated motion control in Malaysian industries.

What Is a Servo Motor?

A servo motor is a rotary or linear actuator that allows for precise control of angular or linear position, velocity, and acceleration. Unlike a standard open-loop motor, a servo motor operates on a closed-loop system using feedback control. This system includes a motor, a sensor (typically an encoder), and a control circuit to ensure highly precise positioning.

What Is a Servo Motor?

How Do Servo Motors Work

The defining feature of a servo motor is its closed-loop operation. This system ensures that the motor’s output matches the commanded input by continuously monitoring the output and correcting any errors.

- Command Signal: The controller (like a PLC or motion controller) sends a command for a desired position, speed, or torque.

- Comparison & Error Signal: Inside the servo drive, the command signal is compared with the feedback signal received from the encoder. Any difference is calculated as an error signal.

- Correction: This error signal is processed by a PID controller (Proportional-Integral-Derivative) algorithm, which determines the necessary voltage/current to drive the motor.

- Action & Feedback: The motor moves, and the encoder constantly measures the actual position/speed, feeding this data back to the drive. This continuous loop ensures that the motor reaches and holds the commanded position with high accuracy.

Key Components of a Servo System

A complete servo system consists of five critical components working in harmony:

| Component | Function |

| Servo Motor | The actuator that converts electrical energy into mechanical motion (rotation or linear). |

| Feedback Device | An encoder or resolver attached to the motor shaft that measures the motor’s current position and speed. |

| Servo Drive | Also known as a servo amplifier, it receives the control signal, calculates the error, and supplies the necessary current/voltage to the motor. |

| Controller | The “brain,” typically a PLC or dedicated motion controller, that issues the movement commands. |

| Transmission | Mechanical components like couplings, ball screws, or a gearbox that transmit the motor’s power to the load. |

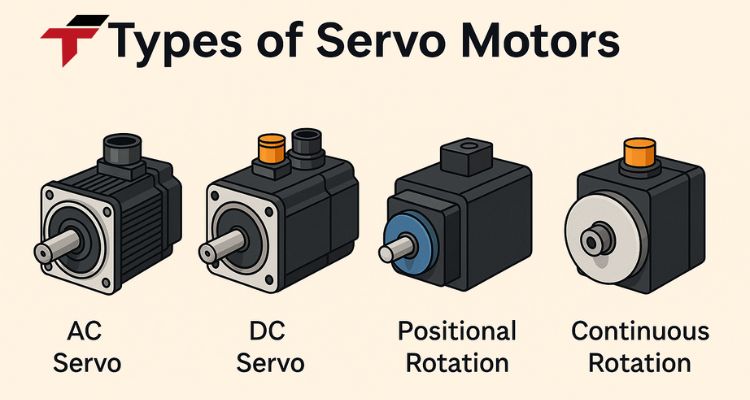

Types of Servo Motors and Their Industrial Uses

The choice of servo motor depends heavily on the application’s required speed, torque, precision, and operating environment. Industrial motor types primarily fall into AC or DC categories, with brushless technology dominating modern automation.

AC Servo Motors

AC servo motors lead the market for high-performance industrial applications in Malaysia.

- Features: They use synchronous motors and are inherently brushless, offering extremely high dynamic response, high power density, and the ability to operate at high speeds.

- Performance: Known for their high precision characteristics, they are ideal for demanding applications requiring continuous, high-speed, and accurate motion.

DC Servo Motors

Traditional DC servos utilize brushes for commutation, making them simpler and often more cost-effective solutions.

- Features: Available in brushed and brushless configurations. Brushed DC servos are simple and suitable for lower-power applications.

- Application Scope: Typically used in smaller low-voltage systems, robotics, and older machinery where high speed and continuous operation are not the primary requirement.

Brushless Servo Motors (BLDC)

The brushless servo (BLDC) is the standard for modern automation due to its superior reliability and low-maintenance operation.

- Features: By eliminating physical brushes, BLDC servos remove a primary point of wear, ensuring a significantly longer life even in challenging or continuous-duty cycles. They offer exceptional efficiency and dynamic capabilities.

- Reliability: The preferred choice for applications in harsh environments like high dust, humidity, or continuous operation (24/7).

Types of Servo Motors and Their Industrial Uses

Servo Motor Applications in Key Industries

Servo systems are the backbone of Malaysian manufacturing automation, enabling the precision necessary for Industry 4.0. They are indispensable for controlling robotics, CNC machines, and high-speed packaging equipment.

Electronics & Semiconductor Manufacturing

Malaysia’s strong electronics and semiconductor sectors rely on ultra-fast and precise motion control.

- Applications: Pick-and-place systems for component assembly, driving axes in Surface Mount Technology (SMT) automation, and high-speed inspection machinery. The need for micron-level accuracy drives the adoption of high-resolution encoders and specialized linear servos.

- Key Requirement: High speed and sub-micron repeatability.

Automotive and Metal Fabrication

From mass production lines to specialized tooling, servos are key to accuracy and power.

- Applications: Driving axes in CNC machines for high-precision machining, controlling spot-welding robot arms, and precise material feeding in metal stamping automation processes.

- Key Requirement: High torque at low speeds and synchronized multi-axis control.

Food & Beverage (F&B) Production Lines

In F&B production, speed and hygiene are critical.

- Applications: High-speed, accurate filling and dosing machines, precise cutting, wrapping, and packaging machines. They are often housed in washdown-rated enclosures (IP65/IP67) for hygienic automation.

- Key Requirement: Speed, synchronization, and compliance with strict sanitary standards.

Logistics, ASRS & Warehouse Automation

The growing demand for e-commerce and fast logistics fuels the need for complex, automated systems.

- Applications: Controlling stacker cranes in Automated Storage and Retrieval Systems (ASRS), driving high-speed sortation, and operating palletizing robot axes.

- Key Requirement: Dynamic speed changes, high acceleration/deceleration, and reliability for 24/7 operation.

Palm Oil Mills & Heavy Industry

Even in heavy industry like palm oil, servos are used for process optimization.

- Applications: Precise valve and damper control, positioning heavy machinery, and high-accuracy material handling in the extraction and refining processes to improve yield and reduce waste.

- Key Requirement: High power, durability, and resistance to harsh, sometimes corrosive, environments.

Communication Protocols and Integration With Automation Systems

Seamless integration is vital for the modern factory floor. Industrial networks in Malaysia rely on high-speed, real-time protocols for servo control.

Common Servo Communication Protocols

Modern automation prioritizes high-speed, deterministic protocols for real-time communication:

- EtherCAT: Known for its speed and high synchronization across many axes, highly favored in high-performance machine control.

- Profinet & CC-Link: Widely used protocols, especially with manufacturers like Siemens and Mitsubishi, forming a robust network foundation in Asian and European-origin systems.

Integrating Servo Motors with HMI & SCADA Systems

HMI (Human-Machine Interface) and SCADA (Supervisory Control and Data Acquisition) systems are essential for monitoring the servo system.

- HMI Motion Display: Operators use the HMI to monitor real-time motor status, set parameters, and execute movement commands.

- SCADA Monitoring: SCADA collects and trends servo data (speed, torque, position error, temperature) for analysis, diagnostics, and predictive maintenance.

Communication Protocols and Integration With Automation Systems

How to Choose the Right Servo Motor for Industries

Selecting the right servo motor is essential to ensure precision, efficiency, and long-term system reliability. For businesses in Malaysia, working with a trusted automation supplier like Flextech makes the selection process smoother, thanks to its strong technical expertise and proven industrial support.

Why choose Flextech as your servo motor partner

- Expert Engineering Support: Flextech’s team assists with sizing, torque calculations, and inertia matching to ensure every motor fits your application perfectly.

- Wide Range of Industrial-Grade Servo Brands: Access to reliable brands that support Malaysia’s diverse industries, F&B, electronics, logistics, automotive, and more.

- Seamless System Integration: Flextech ensures compatibility with PLCs, HMIs, SCADA, and industrial network protocols such as EtherCAT, Profinet, and Modbus.

- After-Sales & Local Technical Service: Fast response, on-site troubleshooting, and genuine spare parts for long-term operational stability.

A well-selected servo motor ensures optimal performance, and partnering with Flextech helps Malaysian industries achieve smoother motion control and greater productivity.