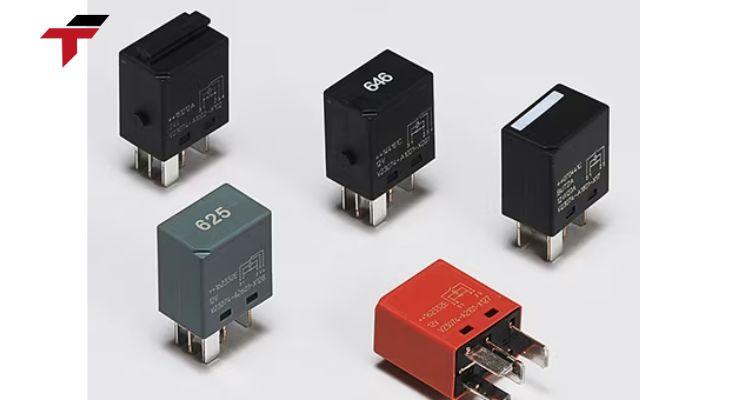

Relays are pivotal electronic devices that serve as control interfaces between different electrical circuits. Their primary function is to manage and switch power flow, often allowing a low-voltage or low-current signal to safely control a high-voltage or high-current load. This capability makes them trusted and widely implemented across virtually every sector requiring electrical management, from industrial machinery to household appliances.

How Electromagnetic Relays Achieve Switching

The functionality of a relay is rooted in the principle of electromagnetic action. A standard relay uses an internal electromagnet to mechanically operate an electrical switch. The process follows three main steps:

- Magnetization: A control current (the input signal) is sent through a coil wound around a metal core, creating a temporary electromagnet.

- Contact Closure: The resulting magnetic field physically pulls an armature towards the core. This movement forces the relay’s electrical contacts to close, completing the main power circuit and allowing a large current to flow to the connected load.

- De-energization: When the control current is removed, the magnetic field collapses instantly. A spring mechanism returns the contacts to their original open position, which breaks the main circuit and shuts off the power to the load.

This electromechanical operation ensures that the vulnerable, low-power control circuit is electrically isolated from the powerful load circuit, providing essential protection and safety.

How Electromagnetic Relays Achieve Switching

Exploring the Main Types of Electrical Relays

Relays are categorized based on their internal operation, allowing engineers to select the best type for a specific application:

- Electromechanical Relays: These are the most traditional type, utilizing the coil and moving contacts system described above. They are versatile, capable of handling AC or DC power, and are widely used due to their simplicity and proven reliability.

- Solid-State Relays (SSRs): These use semiconductor components (like silicon-controlled rectifiers or transistors) instead of mechanical contacts for switching. They are activated by a light signal generated by an internal LED.

- Reed Relays: These feature small, thin metallic contacts (reeds) sealed inside a glass tube filled with inert gas. The gas protects the contacts from environmental damage. A magnetic field causes the reeds to attract and close the circuit.

- Thermal Relays: These are designed primarily for overload protection. They employ a bimetallic strip made of two metals with differing expansion rates. When excessive current causes overheating, the strip bends and physically interrupts the power circuit, protecting machinery like motors from thermal damage.

Diverse Applications and Control Role of Relays

The ability of relays to control power, protect circuits, and facilitate automation has led to their integration across a vast range of systems:

- Industrial Automation: They are essential for controlling high-power equipment, such as starting and stopping large motors and managing industrial safety features like fault detection for overcurrent or overvoltage conditions.

- Transportation Systems: In automatic traffic light controls, relays govern the precise timing and sequencing of the light phases to manage traffic flow efficiently and safely.

- Consumer Electronics: Household items like refrigerators, air conditioners, and washing machines all incorporate relays to control the high-power components, such as compressors and heaters, ensuring stable and reliable device performance.

- Security and Monitoring: Relays are integral to safety systems, including fire alarms (activating warning signals) and surveillance equipment like electric door locks and cameras, enhancing system security.

- Power Management: In complex electronic and computer systems, relays are utilized to distribute power effectively, control power sources, and protect sensitive internal components from harmful voltage fluctuations.

Diverse Applications and Control Role of Relays

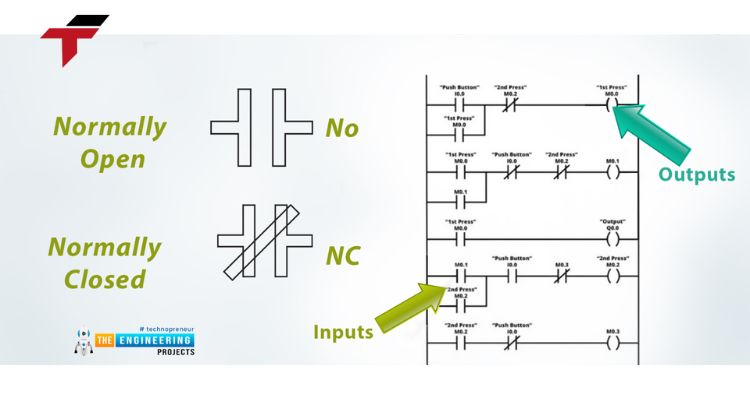

Differentiating Relays from Manual Switches

While both relays and traditional switches perform the basic task of opening or closing a circuit, the method of control defines their appropriate application:

| Characteristic | Relay |

| Activation Method | Electrical current activates an electromagnet. |

| Current/Voltage Capacity | Designed to handle high currents and thousands of volts. |

| Control | Remote and Automatic control. |

| Longevity | High, especially solid-state types which have no mechanical wear. |

| Speed | Typically slower than manual due to electromagnetic response time. |

Guide for Optimal Relay Selection

Choosing the correct relay is crucial for guaranteeing circuit safety, stability, and longevity. Critical factors to evaluate include:

- Rated Voltage and Current: Ensure the relay’s contacts can safely carry and interrupt the maximum current and voltage of the load circuit without arcing or overheating.

- Switching Speed: For applications requiring rapid and frequent cycling, the instant response and durability of a Solid-State Relay (SSR) are preferable. For slower, non-critical timing, electromechanical types suffice.

- Physical Dimensions: Verify the relay’s size is compatible with the mounting location and existing enclosure space.

- Operational Life: Consider the required number of switching cycles. High-duty cycle applications demand relays with superior durability or non-mechanical designs (SSRs).

- Operating Environment: The relay must withstand the ambient conditions, including temperature extremes, humidity, and vibration, to maintain reliable operation.

Relays are the unsung heroes of electrical systems, providing the essential bridge between low-power logic and high-power execution, ensuring efficiency and safety in our automated world.