Simplify your factory automation with AS-Interface (AS-i), the two-wire network solution for sensors and actuators. Designed for speed, reliability, and easy integration, AS-i reduces wiring complexity and keeps production running smoothly. At Flextech, we provide all the components, support, and expertise you need to implement AS-i systems quickly and efficiently.

What Is AS-Interface (AS-i)?

AS-Interface (AS-i) is a widely used industrial networking solution designed for connecting simple field devices like sensors and actuators to higher-level control systems efficiently and cost-effectively.

AS-i is a two-wire bus system that carries both power and digital communication, simplifying wiring and reducing installation costs in automation networks. Developed in the early 1990s, AS-i was created to standardize connectivity for actuators and sensors, making it easier to integrate small devices in manufacturing and process automation.

How Does AS-Interface Work?

To understand AS-i, it’s important to look at how it transmits both data and power over a simple cabling structure.

- Basic Principle: 2-Wire System for Sensors & Actuators AS-i uses just two wires to supply power and enable communication between field devices and controllers.

- Data and Power Transmission Over a Single Cable Both digital signals and DC power are transmitted on the same line, simplifying installation and reducing costs.

- Network Topology: Ring, Line, Star Flexible topologies allow easy integration into various plant layouts.

- Communication Protocol & Addressing Devices Each device on the AS-i network has a unique address for reliable communication and control.

- Integration with PLCs and Higher-Level Control Systems AS-i connects seamlessly with PLCs, SCADA, and other industrial networks for centralized control.

AS-Interface Work

What Are the Key Features of AS-Interface (AS-i)?

AS-Interface (AS-i) is a powerful solution for connecting sensors and actuators in industrial automation. Its design focuses on simplicity, reliability, scalability, and safety, making it ideal for modern factories. The key features include:

- Simple Cabling and Cost-Effective Installation: AS-i uses a two-wire system that carries both power and data, reducing wiring complexity, installation time, and overall costs.

- Fast Communication for Field Devices: Real-time data exchange ensures that sensors and actuators respond quickly, which is crucial for time-sensitive processes like assembly lines, robotics, and automated production cells.

- Support for a Large Number of Devices: Each AS-i network can connect dozens of devices per segment, and the system can be expanded easily, allowing factories to scale automation without major redesigns.

- Robustness in Industrial Environments: AS-i is designed to withstand harsh conditions, including electromagnetic interference, vibrations, moisture, and temperature fluctuations, ensuring reliable operation in demanding industrial settings.

- Integrated Safety Features (AS-i Safety at Work): Supports safety-critical applications by connecting emergency stops, light curtains, and other safety devices on the same network. Compliant with international safety standards (SIL 3 / PL e), it allows safe monitoring and control without extra wiring.

What Are the Advantages of Using AS-Interface (AS-i)?

AS-Interface (AS-i) offers numerous operational benefits that make it an ideal choice for modern industrial automation. Its design enhances efficiency, simplifies wiring, and ensures reliable performance in a wide range of industrial environments. Key advantages include:

- Reduced Installation and Wiring Costs: AS-i’s two-wire system carries both power and data, minimizing cabling requirements, lowering material costs, and speeding up installation.

- Easy System Expansion and Maintenance: Adding or replacing devices is fast and straightforward, allowing plants to scale or modify their automation systems with minimal downtime.

- High Reliability and Durability: Built for harsh industrial conditions, AS-i maintains stable performance even in environments with vibration, moisture, dust, or electromagnetic interference.

- Integration with Other Industrial Networks: AS-i can seamlessly connect to higher-level networks like Profibus, Modbus, or Ethernet/IP, enabling centralized control and flexible automation solutions.

- Enhanced Operational Efficiency: Real-time monitoring and coordinated control improve workflow, reduce bottlenecks, and optimize production processes across the factory.

Reduced Installation and Wiring Costs

What Are the Applications of AS-Interface (AS-i)?

AS-Interface is widely applied in industrial automation due to its simplicity, scalability, and robustness. It can support a variety of production scenarios, connecting field devices efficiently while improving operational performance. Key applications include:

- Assembly Lines & Packaging Systems: Streamlines operations and synchronizes sensors, actuators, and drives to reduce errors and enhance throughput.

- Conveyor Systems & Material Handling: Provides reliable control of motors, sensors, and actuators for smooth material flow and minimized stoppages.

- Robotics & Automated Production Cells: Ensures safe and precise real-time communication between robots and controllers in automated cells.

- Hazardous or Harsh Environments: Designed to operate reliably in tough conditions, including high vibration, dust, moisture, or areas requiring intrinsic safety.

- Field Devices (Sensors, Actuators, Valves): Simplifies connection of multiple small devices directly to the network, reducing cabling complexity while enabling centralized monitoring and control.

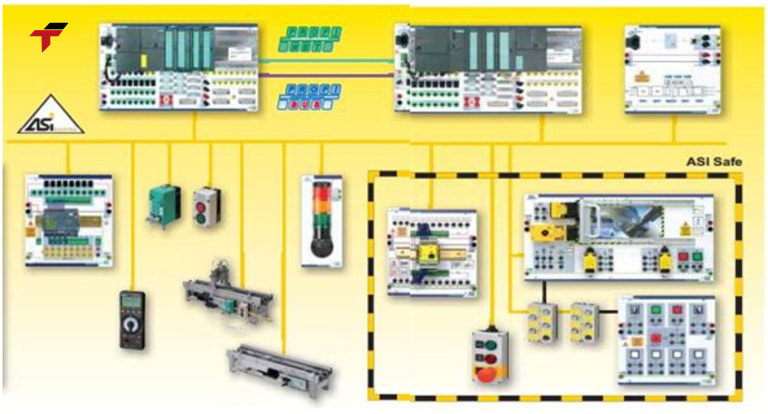

What Are the Components of an AS-Interface (AS-i) System?

To implement an effective AS-Interface network, it is important to understand its core components. Each part plays a specific role in ensuring reliable communication, power delivery, and seamless integration with industrial automation systems. Key components include:

- AS-i Master: The central controller that manages communication across the network and assigns unique addresses to each connected device, ensuring organized and efficient data flow.

- AS-i Power Supply: Provides both electrical power and data transmission over the same two-wire cable, simplifying installation and maintaining stable operation for all connected devices.

- AS-i Slaves (Sensors and Actuators): Field devices such as sensors, actuators, and valves that collect or execute process data, connected directly to the AS-i bus for real-time operation.

- AS-i Couplers & Gateways: Devices that interface the AS-i network with higher-level systems like PLCs, SCADA, or other industrial networks, enabling centralized monitoring and control.

- Cables and Connectors: Two-wire bus cables and compatible connectors that carry both power and communication signals, designed for easy installation and reliable performance in industrial environments.

Each part plays a specific role in ensuring reliable communication, power delivery, and seamless integration with industrial automation systems

Conclusion

AS-Interface (AS-i) is a cost-effective, reliable, and scalable solution for connecting sensors and actuators in modern industrial automation. It simplifies wiring, improves operational efficiency, and supports safety standards for critical applications.

As a trusted provider of industrial automation solutions, Flextech offers high-quality AS-i masters, slaves, power supplies, and accessories, along with technical support and system integration services, ensuring efficient and seamless deployment in your factory.