Remote Access has become one of the most valuable technologies in modern industrial automation. As industries deal with geographically dispersed sites, labour shortages, and rising demands for operational uptime, the ability to remotely monitor, control, and troubleshoot equipment is no longer just an advantage. It’s a necessity. This guide explores what remote access actually is, how it works, and why it plays a crucial role in improving efficiency, reliability, and safety across industrial facilities.

What Is Remote Access in Industrial Automation?

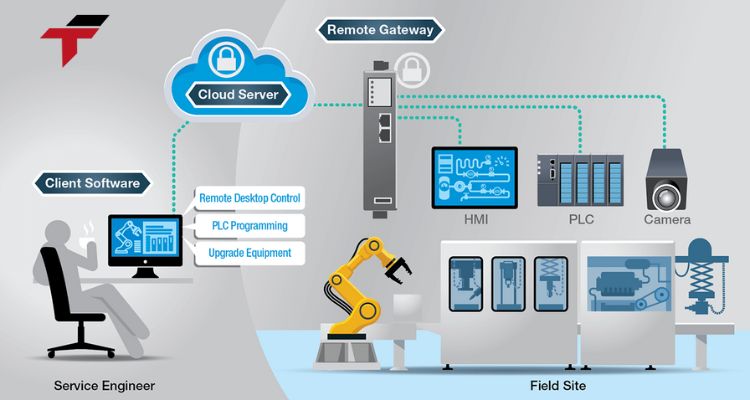

Remote access refers to the capability that allows engineers, technicians, and operators to connect to industrial equipment such as PLCs, HMIs, SCADA systems, sensors, and robotics without being physically present onsite. Through secure connectivity methods like industrial VPNs, encrypted gateways, and cloud-based IIoT platforms, teams can perform diagnostics, update programs, monitor real-time performance, and take corrective action from anywhere.

In remote and regional sectors such as mining, agriculture, manufacturing, and oil & gas, remote access offers significant operational benefits by reducing travel time, minimising downtime, and enhancing workforce efficiency.

What Is Remote Access in Industrial Automation?

How Remote Access Works

A typical remote access architecture includes:

- Industrial Devices: PLCs, HMIs, industrial PCs, sensors, drives, and controllers located at the facility.

- Connectivity Hardware: Secure remote access gateways, industrial routers, VPN devices, or cloud connectors.

- Secure Tunnelling: Encrypted connections (TLS, SSL, IPSec) that protect data between the site and the engineer.

- Remote Access Platform: Software portals or IIoT platforms that allow technicians to log in, view equipment status, perform troubleshooting, or update control logic.

- User Authentication: Multi-factor authentication (MFA), role-based permissions, and audit logs to ensure security.

This structure ensures safe, controlled access while preventing unauthorised entry into critical Operational Technology (OT) networks.

Key Benefits of Remote Access

Remote access provides faster troubleshooting, reduces downtime, improves safety, and lowers maintenance costs while enhancing visibility and operational efficiency across various industrial environments.

- Faster Troubleshooting and Reduced Downtime: Remote access allows technicians to diagnose and fix issues within minutes rather than hours or days. According to McKinsey, predictive and remote maintenance strategies can cut downtime by 20–35%, resulting in significant cost savings, especially for industries operating 24/7.

- Lower Operational and Maintenance Costs: Engineers can support multiple facilities without frequent travel. This is particularly valuable, where remote sites may be hundreds of kilometres apart.

- Enhanced Workforce Productivity: Automation teams can manage assets in real time, focus on strategic tasks, and respond quickly to system alerts.

- Improved Safety: Less travel to harsh or hazardous environments reduces worker exposure to risk. Mining, oil & gas, and water utilities benefit significantly from this.

- Better Visibility and Data Insights: Cloud-enabled remote access platforms allow real-time equipment monitoring and long-term performance analytics, supporting optimisation and preventive maintenance.

Key Benefits of Remote Access

Where Remote Access Is Used

Remote access is widely used across industries to monitor, troubleshoot, and control equipment remotely. It enhances efficiency, minimises downtime, and facilitates safe, real-time system support across mining, manufacturing, energy, agriculture, and logistics.

Mining Operations

The industry’s mining sector relies heavily on remote locations and distributed assets. Remote access makes it possible to:

- Monitor conveyor systems

- Diagnose PLC or drive issues instantly

- Support autonomous equipment and remote operation centres (ROCs)

Manufacturing Facilities

Remote access helps plant managers:

- Troubleshoot SCADA alarms

- Update PLC logic during off-hours

- Track machine performance in real time

Oil & Gas / Energy

Operators can:

- Monitor pipeline pressures

- Support SCADA remote troubleshooting

- Manage remote compressors or pumping stations safely

Agriculture & Irrigation

Modern agritech systems use remote access for:

- Pump control

- Weather station monitoring

- Automated irrigation management

Logistics & Warehousing

Remote access enables technicians to support:

- Conveyor systems

- ASRS (Automated Storage & Retrieval Systems)

- HMI and SCADA dashboards across distributed sites

Remote Access Technologies and Tools

Remote access technologies and tools enable secure, real-time connectivity to industrial equipment from anywhere. They combine VPNs, IIoT gateways, monitoring platforms, and advanced security features to improve reliability, efficiency, and remote troubleshooting capabilities.

- Industrial VPN: A secure VPN creates an encrypted tunnel between the engineer and the industrial device. VPNs are reliable but require proper configuration and strict access control.

- Cloud-Based IIoT Gateways: IIoT platforms allow secure, controlled remote connectivity without exposing the OT network. They typically offer: Device dashboards, trend analysis, remote firmware updates and secure tunnelling for PLC/HMI programming.

- Remote Monitoring Platforms: These platforms provide real-time asset monitoring, alarm notifications, and data analytics across multiple sites.

- Zero-Trust Architectures: Increasingly used in OT environments, zero-trust ensures every user, device, and request is verified before accessing the system.

Remote Access Technologies and Tools

Cybersecurity Considerations for Remote Access

With the rise of remote connectivity, OT cybersecurity risks have increased significantly. Reports show OT-related cyber incidents have grown by over 50% year-over-year, highlighting the need for secure access methods.

To ensure safe remote operations, companies should follow these best practices:

- Enforce Multi-Factor Authentication (MFA): Adds an essential layer of protection for remote logins.

- Use Role-Based Access Control (RBAC): Ensure users can only access equipment relevant to their role.

- Segment IT and OT Networks: Prevent lateral movement in case of a security breach.

- Implement Encrypted Tunnels: TLS/SSL or IPSec ensures secure data transmission.

- Monitor and Log All Remote Sessions: Audit logs help detect suspicious behaviour and maintain compliance.

- Keep Firmware and Software Updated: Outdated gateways or PLC firmware can become common attack vectors.

Why Choose Flextech for Your Remote Access and Industrial Automation Needs?

Flextech provides a comprehensive suite of remote access solutions designed to enhance system visibility, streamline maintenance, and improve operational efficiency. Here are four key reasons to choose Flextech:

- Advanced Remote Access Technology: We leverage secure VPNs, IIoT gateways, and smart connectivity tools to deliver reliable, real-time access to your automation systems.

- Tailored Remote Access Solutions: Our services are customised to match your facility’s specific equipment, workflows, and security requirements.

- Efficiency and Cost Reduction: We help minimise downtime, reduce onsite travel, and optimise maintenance processes through fast and secure remote support.

- End-to-End Support: From system installation to remote access training and ongoing technical assistance, we ensure your team can operate confidently and securely.

Partnering with Flextech means enhancing operational visibility, increasing uptime, and improving productivity through trusted, secure, and scalable remote access solutions.