In today’s competitive manufacturing environment, precision, efficiency, and consistency are more critical than ever. Direct Numerical Control (DNC) systems allow manufacturers to centralize control of multiple CNC machines, streamline operations, and maintain high-quality production. By integrating DNC, factories can reduce downtime, optimize machine utilization, and gain real-time insights into their processes, making it an essential component of modern smart manufacturing solutions.

What is Direct Numerical Control (DNC)?

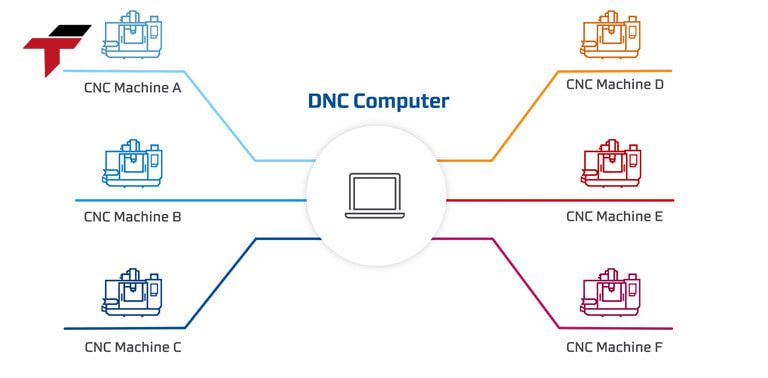

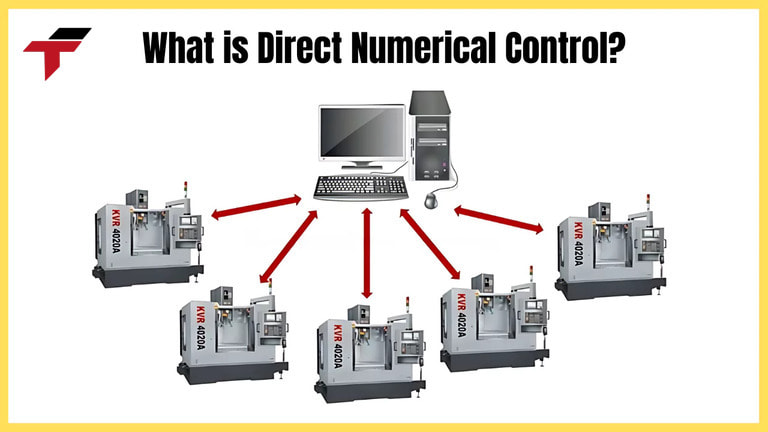

Direct Numerical Control (DNC) is a system that allows a central computer to directly control multiple CNC (Computer Numerical Control) machines in a manufacturing environment. Unlike standalone CNC machines, DNC enables centralized program management and real-time monitoring.

Importance of DNC in modern manufacturing:

- Ensures consistent production quality across multiple machines.

- Reduces downtime by quickly distributing part programs to machines.

- Supports large-scale production environments and complex operations.

What Are the Key Components of a DNC System?

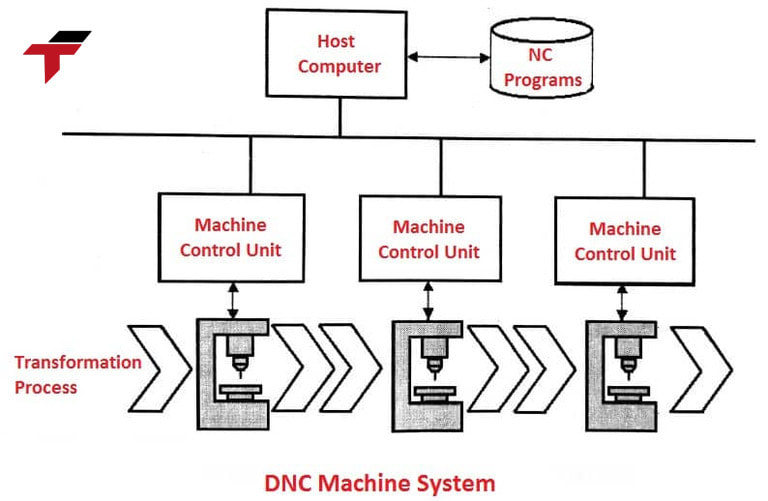

In modern manufacturing, a Direct Numerical Control (DNC) system is more than just a connection between machines and a computer—it is a carefully coordinated network that ensures CNC machines operate efficiently, accurately, and consistently.

Understanding the core components of a DNC system helps manufacturers optimize production and reduce downtime.

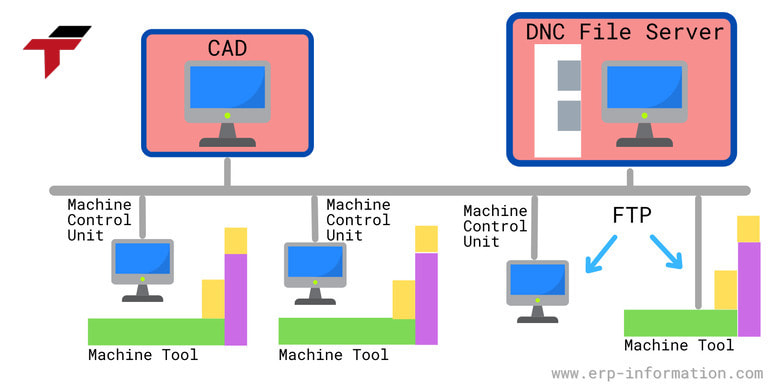

Central Computer or Server

The central computer serves as the brain of a DNC system. It stores all part programs, operational parameters, and production schedules in a secure and organized manner.

- Stores all part programs, operational parameters, and production schedules securely.

- Centralizes data to eliminate the need for machines to store programs locally, reducing errors.

- Monitors machine performance, queues jobs, and ensures the correct program reaches the correct machine on time.

CNC Machines

CNC (Computer Numerical Control) machines are the executors of production in a DNC system. These machines receive part programs directly from the central computer, allowing them to perform precise cutting, drilling, milling, or shaping operations.

- Receive part programs directly from the central computer.

- Operate continuously without manual intervention for program updates.

- Maintain consistent quality across multiple machines.

Communication Network (Wired or Wireless)

A reliable communication network forms the backbone of a DNC system. It connects the central computer to all CNC machines and ensures fast, secure, and accurate data transfer.

- Ensures fast, secure, and accurate data transfer.

- Wired options (Ethernet, RS-232) provide stability; wireless offers flexibility for dynamic layouts.

- Supports real-time monitoring and feedback for quick issue detection.

DNC Software for Program Management

DNC software acts as the control interface between the central server and CNC machines. It manages version control, schedules job queues, and tracks program execution.

- Manages version control and schedules job queues.

- Tracks program execution and machine utilization.

- Provides analytics, error detection, and integrates with ERP/MES systems for smart manufacturing.

- Ensures streamlined, organized, and scalable production.

Key Components of a DNC System

What Are the Advantages of Using DNC?

In today’s competitive manufacturing environment, efficiency, accuracy, and consistency are critical. Direct Numerical Control (DNC) systems offer significant advantages over standalone CNC machines by centralizing control, streamlining operations, and providing valuable insights into production.

- Centralized Program Management: Simplifies updates by storing all part programs in a single location. Reduces errors caused by manual copying to individual machines. Maintains consistent production quality by ensuring all machines use the latest program version.

- Reduced Machine Downtime: Programs are sent directly to machines instantly over the network. Eliminates delays caused by manual program transfers. Minimizes idle time and allows machines to operate continuously.

- Improved Production Efficiency and Consistency: Ensures all machines follow standardized instructions. Automates program distribution, reducing operator intervention. Optimizes machine utilization and maintains uniform part quality.

- Enhanced Data Tracking and Reporting: Collects real-time data on machine performance and program execution. Detects errors early, preventing costly mistakes. Provides insights for process optimization, maintenance planning, and continuous improvement.

Advantages of Using DNC

Where Is DNC Commonly Used?

In modern manufacturing, different industries face unique challenges in production volume, complexity, and precision requirements. Direct Numerical Control (DNC) systems provide a centralized and efficient solution, allowing CNC machines to operate consistently and accurately across a wide range of applications. The following industries commonly benefit from implementing DNC:

- Automotive Industry: High-volume, repetitive production requiring precision. Ensures consistent quality across multiple machines. Supports fast program changes for different vehicle models.

- Aerospace Manufacturing: Handles complex part programs with strict tolerances. Maintains accuracy for safety-critical components. Facilitates program updates for custom and small-batch parts.

- Metal Fabrication: Used in sheet metal, stamping, and machining processes. Ensures uniformity and precision in cutting and forming operations. Reduces errors and increases throughput.

- Tool and Die Shops: Ideal for custom parts with frequent program updates and revisions. Enables fast distribution of new programs to multiple machines. Maintains high-quality standards for molds and dies.

In modern manufacturing, different industries face unique challenges in production volume, complexity, and precision requirements.

What Challenges Should Manufacturers Consider When Using DNC?

Implementing a Direct Numerical Control (DNC) system can greatly enhance manufacturing efficiency, but it also comes with certain challenges that manufacturers need to consider. Being aware of these factors helps in planning a smooth integration and maximizing the benefits of DNC.

- Initial Setup Cost and Integration Complexity: Installing a DNC system requires investment in hardware, software, and network infrastructure. Integrating with existing CNC machines and factory systems may involve additional time and resources.

- Network Security and Reliability: DNC systems depend on stable communication between the central computer and CNC machines. Network failures, interruptions, or security breaches can halt production and lead to data loss.

- Compatibility with Older CNC Machines: Legacy machines may not be directly compatible with modern DNC systems. Retrofitting or using adapters may be necessary to connect older equipment, adding complexity to the setup.

- Training Requirements for Staff: Operators and maintenance personnel need proper training to use the DNC system effectively. Understanding program management, troubleshooting, and real-time monitoring is crucial to fully leverage the system’s capabilities.

Being aware of these factors helps in planning a smooth integration and maximizing the benefits of DNC

Conclusion

In conclusion, Direct Numerical Control (DNC) systems play a vital role in modern manufacturing by centralizing program management, improving production efficiency, reducing machine downtime, and providing valuable data insights. By addressing challenges such as setup costs, network reliability, and staff training, manufacturers can fully leverage the advantages of DNC to achieve consistent, high-quality production.

At Flextech, we specialize in providing comprehensive automation solutions, including DNC integration, CNC connectivity, and advanced manufacturing technologies. Our team helps factories optimize operations, implement reliable systems, and stay at the forefront of Industry 4.0. Whether upgrading legacy equipment or deploying a fully integrated DNC network, Flextech is your trusted partner in smart manufacturing solutions.