In modern factories, real-time monitoring, predictive maintenance, and operational optimization are essential. An Advanced Plant Management System (APMS) integrates machines, sensors, and control systems to enhance efficiency, improve product quality, and enable data-driven decision-making. Flextech provides reliable components and solutions to help manufacturers implement APMS and take their operations to the next level.

What Is an Advanced Plant Management System (APMS)?

An Advanced Plant Management System (APMS) is an integrated digital platform designed to monitor, coordinate, and optimize every aspect of plant operations. It connects machines, sensors, control systems, and enterprise applications to provide a unified view of production performance, asset health, and resource utilization across the entire facility.

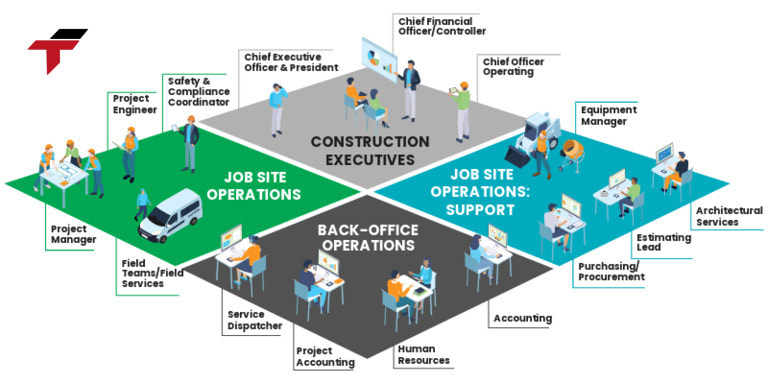

The Role of APMS in Plant Management & Operations

APMS serves as the “central intelligence” of the factory by:

- Providing real-time visibility into production processes

- Coordinating workflows across departments and equipment

- Enabling data-driven decision-making

- Enhancing operational efficiency, safety, and consistency

- Supporting continuous improvement and smart manufacturing initiatives

It ensures that production, maintenance, quality, and management teams all operate based on the same accurate, real-time data.

What Are the Core Functions of an Advanced Plant Management System?

To understand why APMS is crucial for modern industrial operations, it’s important to look at the key functions it provides. These functions help plants monitor processes in real-time, optimize operations, maintain equipment, ensure quality, and enhance safety across the entire facility.

- Real-Time Data Monitoring: APMS consolidates data from sensors, machines, and control systems into a single dashboard, allowing operators to track production status, equipment conditions, and process variables instantly. This enables faster reaction to deviations and improves overall transparency.

- Plant-Wide Coordination and Operational Optimization: By analyzing production flows and resource usage, APMS helps balance workloads, eliminate bottlenecks, and synchronize processes across departments. It ensures that machines, materials, and labor operate in harmony to maximize throughput.

- Asset Management & Predictive Maintenance: APMS monitors equipment performance and historical patterns to detect early signs of wear or failure. Using predictive analytics, it can recommend maintenance before breakdowns occur—reducing downtime, extending asset life, and lowering repair costs.

- Quality Control & Data Traceability: The system tracks quality parameters throughout production and links them to batches, machines, and operators. This supports consistent product quality, faster root-cause analysis, and full traceability for audits and compliance requirements.

- Performance Reporting & Analytics (OEE, KPIs): APMS calculates key performance indicators such as Overall Equipment Effectiveness (OEE), uptime, cycle times, and yield. It provides automated reports and advanced analytics to help managers evaluate performance and identify improvement opportunities.

- Safety & Incident Management: APMS can detect abnormal conditions, trigger alarms, and log incidents for further analysis. It supports safety compliance, risk prevention, and rapid response to equipment or process failures—helping protect personnel, assets, and the environment.

These functions help plants monitor processes in real-time, optimize operations, maintain equipment

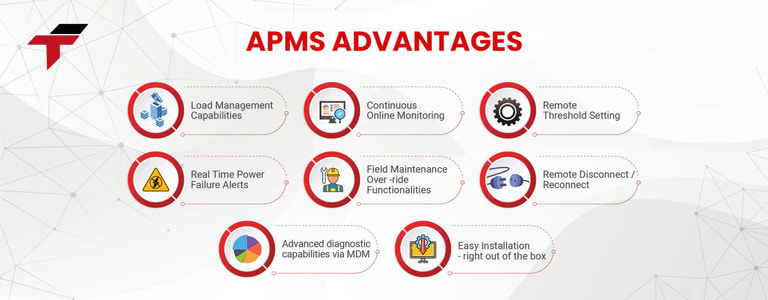

What Are the Key Benefits of APMS for Businesses?

Implementing an Advanced Plant Management System (APMS) brings multiple advantages for industrial operations. Key benefits include:

- Reduce Downtime & Increase Efficiency: Real-time monitoring detects issues early, minimizing unplanned stops and keeping production flowing smoothly.

- Improve Product Quality & Stability: Tracks quality parameters across production, ensuring consistency and reducing defects.

- Lower Maintenance & Operational Costs: Predictive maintenance and optimized workflows reduce repair costs and resource waste.

- Optimize Energy & Resource Usage: Monitors consumption patterns to identify inefficiencies and promote sustainable operations.

- Enhance Data-Driven Decision Making: Consolidates production and performance data into actionable insights for faster, smarter decisions.

Implementing an Advanced Plant Management System (APMS) brings multiple advantages for industrial operations

How Does APMS Compare to Existing Systems?

APMS differs from traditional industrial systems like SCADA, MES, and ERP by integrating multiple layers into a single platform. Key points of comparison include:

- APMS vs SCADA: While SCADA supervises and visualizes processes, APMS extends its data to plant-wide optimization and predictive analytics.

- APMS vs MES: MES manages production execution and scheduling, but APMS integrates process control, asset management, and analytics for holistic operations.

- APMS vs ERP: ERP handles enterprise-level business processes; APMS complements it by managing OT data in real-time and linking operational insights to business decisions.

Overall Advantages: APMS provides unified monitoring, predictive maintenance, and performance optimization across the entire plant, offering a more comprehensive solution than individual systems.

Notes when using Advanced Plant Management System

When using Advanced Plant Management System (APMS), there are some important notes to consider to ensure maximum efficiency and avoid problems arising during the implementation and operation of the system

- Ensure compatibility with existing systems: Integrating legacy systems with APMS can be difficult without a clear plan and appropriate conversion tools.

- Training and staff development: Ensure that employees are properly trained on how to use the system to maximize its features, minimize errors and increase productivity.

- Evaluate implementation and maintenance costs: APMS implementation requires an initial investment of USD 30,000-50,000. These costs need to be carefully evaluated and compared with the long-term benefits that the system brings to ensure that investing in APMS is reasonable and economically effective.

- Continuous monitoring and evaluation of performance: To ensure that the APMS delivers the expected results, it is necessary to establish key performance indicators (KPIs) related to production performance, cost savings, product quality, and maintenance.

- Ensure data security: Businesses need to apply data security measures such as encryption, user authentication, and monitoring for unusual activities to protect the system from cyber attacks or data loss risks.

Notes when using Advanced Plant Management System

What Are the Applications of an Advanced Plant Management System (APMS)?

Advanced Plant Management Systems (APMS) are designed to optimize operations across a wide range of industries. By integrating data from field devices, control systems, and enterprise applications, APMS enables real-time monitoring, predictive maintenance, and operational optimization. Key applications include:

- Manufacturing Plants & Automated Production Lines: Streamlines production workflows, monitors machine performance, and improves overall equipment efficiency (OEE).

- Food & Beverage Industry: Ensures consistent product quality, maintains hygiene compliance, and optimizes production scheduling.

- Chemical, Oil & Gas, and Hazardous Environments: Supports intrinsic safety, monitors process variables in high-risk areas, and reduces operational risks.

- Power & Energy Sector: Enhances monitoring of turbines, substations, and renewable energy assets while optimizing energy consumption.

- Water & Wastewater Treatment: Tracks sensors, valves, and pumps across wide facilities, supporting centralized monitoring and efficient resource management.

- Field Instruments (Sensors, Actuators, Transmitters): Integrates diverse devices for real-time data acquisition, predictive maintenance, and operational control.

Applications of an Advanced Plant Management System (APMS)

Conclusion

An Advanced Plant Management System (APMS) helps factories reduce downtime, optimize resources, and improve product quality. For manufacturers looking to implement smart, efficient operations, Flextech provides reliable automation components, technical support, and integration solutions to make APMS deployment seamless and effective.