Automatic box-opening technology transforms packaging and warehouse operations by automating the opening of boxes with precision, speed, and minimal manual labor. Using sensors, cutting mechanisms, and smart integration with conveyors and robotic systems, it increases throughput, reduces labor costs, and enhances safety. At Flextech, we provide high-quality automatic box-opening machines, customized solutions, and expert support to help warehouses and factories streamline operations and achieve efficient, scalable automation.

What Is Automatic Box-Opening Technology?

Automatic box-opening technology refers to machines and systems designed to open cardboard boxes or cartons automatically, without the need for manual labor. This technology is widely used in modern warehouses, fulfillment centers, and manufacturing plants to increase speed, accuracy, and safety in handling packaged goods.

It is a type of automation system that detects, cuts, and opens boxes, allowing products inside to be accessed or processed efficiently. It minimizes manual intervention, reducing repetitive strain and human error.

Manual box-opening is time-consuming, labor-intensive, and error-prone. Automated systems allow warehouses and factories to process higher volumes of goods faster, improve workplace safety, and integrate seamlessly with other automated handling or sorting systems.

How Does Automatic Box-Opening Technology Work?

Automatic box-opening systems combine mechanical, electronic, and software components to detect, open, and process boxes accurately.

- Overview of the Box-Opening Process: Boxes move along a conveyor, are identified by sensors, and positioned for cutting or opening. The system then executes the opening operation safely and precisely.

- Sensors and Detection Systems: Optical sensors, barcode readers, and weight sensors detect box position, size, and content, ensuring proper alignment before opening.

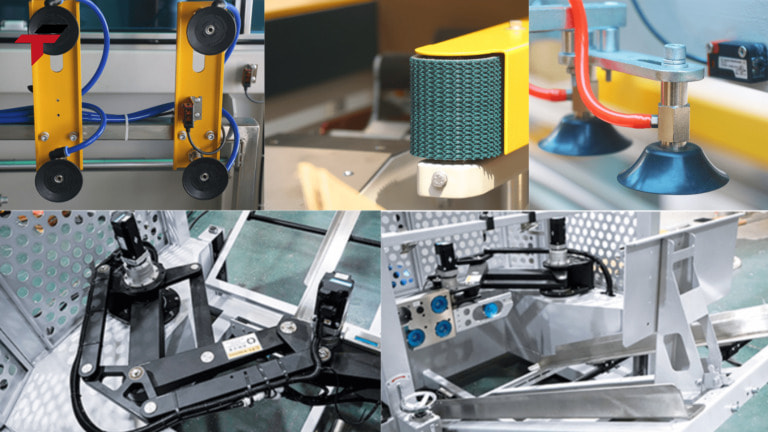

- Cutting and Opening Mechanisms: Machines use blades, lasers, or rollers to cut tape or open flaps. Advanced systems adjust cutting depth and angle based on box material and thickness.

- Integration with Conveyor Systems: The box-opener works in harmony with conveyor belts, ensuring smooth throughput without slowing down the production line.

- Connection with WMS and Robots: Many systems communicate with warehouse management systems (WMS) and robotic handling units, allowing automated sorting, packing, or processing downstream.

Automatic box-opening systems combine mechanical, electronic, and software components

What Are the Key Features of Automatic Box-Opening Technology?

Automatic box-openers are designed to maximize speed, flexibility, and safety. Key features include:

- High-Speed Operation and Accuracy: Systems can process hundreds of boxes per hour, maintaining consistent accuracy and reducing manual handling errors.

- Handling Different Box Sizes and Materials: Adjustable cutting mechanisms allow the machine to accommodate various box dimensions and material types, from thin cardboard to thicker cartons.

- Safety Mechanisms to Protect Operators and Products: Sensors and safety shields prevent contact with moving blades or lasers, ensuring operator safety and protecting contents from damage.

- Minimal Manual Intervention: Once configured, the system runs automatically, reducing the need for human oversight and freeing staff for other tasks.

- Compatibility with Existing Packaging Lines and Robotics: Can integrate with conveyor belts, robotic pickers, and automated sorting systems, ensuring smooth operations in modern warehouses and manufacturing facilities.

Automatic box-openers are designed to maximize speed, flexibility, and safety

What Are the Advantages of Using Automatic Box-Opening Technology?

Implementing automatic box-opening systems provides significant operational and financial benefits for warehouses, fulfillment centers, and factories:

- Increased Productivity and Throughput: Automation allows continuous box processing, improving overall workflow efficiency and reducing bottlenecks.

- Reduced Labor Costs: Fewer workers are needed for repetitive manual box-opening, lowering operational expenses while allowing human staff to focus on higher-value tasks.

- Improved Workplace Safety: Automated systems eliminate repetitive cutting tasks that can cause strain or injury, creating a safer working environment.

- Lower Risk of Product Damage: Precise opening mechanisms and sensors minimize mistakes, protecting fragile or sensitive products during the process.

- Integration with Automated Fulfillment and Sorting Systems: Works seamlessly with robotic pickers, conveyor systems, and sorting units, enabling fully automated supply chain and logistics operations.

Advantages of Using Automatic Box-Opening Technology

Where Is Automatic Box-Opening Technology Applied?

Automatic box-opening technology is widely used across industries that require high-speed packaging, warehousing, and fulfillment, helping to streamline operations and reduce labor requirements. Key applications include:

- E-commerce and Retail Fulfillment Centers: Automates the opening of large volumes of packages, allowing faster order processing, sorting, and shipping, which is critical for online retail operations.

- Food and Beverage Packaging: Ensures hygienic and consistent box-opening for products like canned goods, beverages, or bulk food items, reducing the risk of contamination or spillage.

- Electronics and Consumer Goods Manufacturing: Handles fragile or sensitive items carefully, preventing damage during the opening process while increasing processing speed.

- Logistics and Distribution Centers: Integrates with conveyor systems and sorting robots to automate inbound and outbound package handling, improving overall throughput and accuracy.

- Pharmaceutical and Healthcare Packaging: Maintains strict safety and quality standards while opening boxes containing medical supplies, pharmaceuticals, or healthcare products, minimizing human contact and errors.

What Are the Challenges and Considerations in Automatic Box-Opening Technology?

While automatic box-opening systems offer numerous benefits, several challenges must be addressed to ensure smooth implementation and operation:

- Initial Investment and Installation Cost: Purchasing and installing automatic box-opening machines and integrating them into existing production lines can require significant upfront capital.

- Handling Non-Standard or Damaged Boxes: Irregularly sized, shaped, or damaged boxes may require advanced sensors or manual intervention, limiting fully automated efficiency.

- Maintenance and Wear of Cutting Mechanisms: Blades, lasers, and rollers are subject to wear and tear, requiring routine maintenance to maintain precision and prevent downtime.

- Integration with Existing Automation and WMS Systems: Compatibility with current warehouse management systems, conveyors, and robotic systems must be carefully planned to avoid workflow disruptions.

- Safety Compliance and Operator Training: Machines must adhere to safety regulations, and operators need training to monitor, troubleshoot, and maintain the systems safely.

Challenges and Considerations in Automatic Box-Opening Technology

How Can Flextech Help With Automatic Box-Opening Technology?

At Flextech, we provide comprehensive solutions for implementing automatic box-opening systems in warehouses, manufacturing plants, and fulfillment centers:

- Supply of Automatic Box-Opening Machines: Offering a range of machines suitable for different box sizes, materials, and production volumes.

- Customization for Different Box Sizes and Production Lines: Tailored solutions ensure seamless integration with existing conveyor systems and automation workflows.

- Technical Support, Maintenance, and Integration Services: Full support for installation, calibration, and ongoing maintenance, minimizing downtime and maximizing system efficiency.

- Consulting for Warehouse Automation Efficiency: Expert guidance on optimizing workflows, integrating robotics, and scaling automation, helping clients achieve faster, safer, and more cost-effective operations.