GE Automation & Controls offers cutting-edge technologies designed to streamline industrial operations and maximize efficiency. From automating complex processes to providing real-time insights, GE solutions empower businesses to reduce downtime, improve accuracy, and stay competitive. In this article, we’ll explore the main products, benefits, and applications of GE Automation & Controls and how Flextech can support seamless implementation.

What is GE Automation & Controls?

GE Automation & Controls is a leading provider of industrial automation solutions designed to optimize manufacturing and production processes. It encompasses a wide range of hardware, software, and control systems that enable businesses to automate, monitor, and manage industrial operations with precision and efficiency.

The product portfolio of GE Automation & Controls includes programmable logic controllers (PLCs), human-machine interfaces (HMIs), supervisory control and data acquisition (SCADA) systems, industrial I/O modules, sensors, and industrial networking solutions. These components work together to create intelligent automation systems that improve operational reliability, reduce downtime, and enhance overall productivity.

By leveraging GE Automation & Controls, industries can implement scalable and flexible automation strategies, integrate with the Industrial Internet of Things (IIoT), and drive digital transformation initiatives across manufacturing, energy, oil & gas, and other sectors.

What Are the Main Products and Solutions Offered by GE Automation & Controls?

GE Automation & Controls provides a comprehensive suite of products and solutions to meet diverse industrial automation needs:

- Programmable Logic Controllers (PLCs): Industrial-grade controllers for managing and automating manufacturing processes, from simple operations to complex multi-line systems.

- Human-Machine Interfaces (HMIs): Intuitive interfaces that allow operators to monitor, control, and interact with automated equipment in real time.

- Supervisory Control and Data Acquisition (SCADA) Systems: Software solutions for remote monitoring, process visualization, and data collection to optimize operations.

- Industrial I/O Modules and Sensors: Devices for collecting signals from machinery and converting them into actionable data for the control system.

- Industrial Networking Solutions: Ethernet and fieldbus communication systems that connect devices, controllers, and software platforms for seamless automation.

- Software Solutions: Tools for programming, simulation, and analytics that enhance system performance and support predictive maintenance.

These solutions are designed to be scalable, reliable, and compatible with existing systems, allowing industries to implement flexible automation strategies tailored to their operational needs.

GE Automation & Controls provides a comprehensive suite of products and solutions to meet diverse industrial automation

How Does GE Automation & Controls Help Optimize Industrial Processes?

GE Automation & Controls enhances industrial efficiency and productivity through:

- Process Automation: Automates repetitive and complex tasks to minimize human intervention, reduce errors, and maintain consistent quality.

- Real-Time Monitoring: Provides live data on equipment performance, production metrics, and process conditions for immediate decision-making.

- Predictive Maintenance: Utilizes sensors and data analytics to anticipate equipment failures, reducing downtime and maintenance costs.

- Energy and Resource Optimization: Monitors and controls energy consumption and material usage to lower operational costs.

- Integration with IIoT and Industry 4.0 Technologies: Connects devices, software, and analytics platforms for intelligent, data-driven operations.

By implementing GE Automation & Controls, businesses can achieve higher productivity, improved process reliability, and faster response to market demands, enabling them to stay competitive in the digital industrial era.

GE Automation & Controls enhances industrial efficiency and productivity through

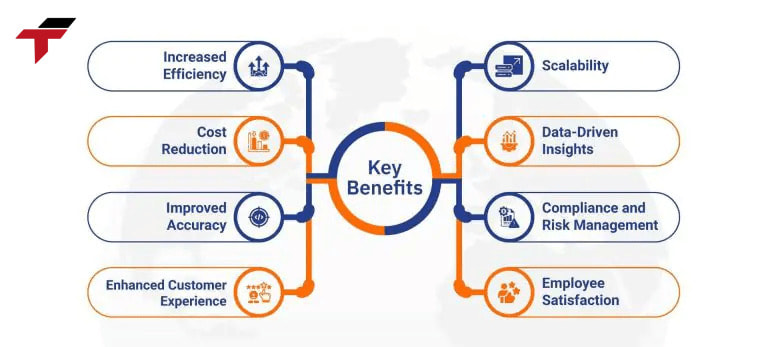

What Are the Key Benefits of Using GE Automation & Controls?

GE Automation & Controls brings many outstanding benefits, helping businesses improve production efficiency and compete in the market. Here are the detailed benefits:

- Increase productivity and efficiency: GE Automation & Controls helps businesses optimize production processes through modern automation solutions. By minimizing machine downtime and optimizing operational performance, companies can significantly improve productivity and maintain stable operations, achieving production goals faster and more efficiently.

- Improve product quality: GE Automation & Controls systems are designed to ensure quality control at every production stage. Advanced solutions help minimize errors, maintain product quality consistency, and enhance the reputation of businesses in the market.

- Enhance competitiveness: In an increasingly competitive market, applying advanced technology from GE Automation & Controls helps businesses quickly respond to market and customer needs. Moreover, the system’s flexible customization capabilities are suitable for many different industries, helping businesses maintain their position and develop sustainably.

- High reliability: GE Automation & Controls solutions are designed with high quality standards, ensuring stable operation even in harsh environmental conditions. With comprehensive technical support from GE’s team of experts, businesses can operate the system with peace of mind without worrying about technical risks.

GE Automation & Controls brings many outstanding benefits

What Are the Challenges and Considerations When Implementing GE Automation & Controls?

While GE Automation & Controls provides powerful solutions, there are several considerations and potential challenges:

- High Initial Investment: Deploying GE’s automation systems may require significant capital for hardware, software, and integration services.

- System Complexity: Large-scale implementations require careful planning, skilled personnel, and proper configuration to ensure smooth operation.

- Integration with Legacy Systems: Existing machinery or older control systems may need customization or adapters to integrate seamlessly.

- Training and Expertise: Staff must be trained to operate and maintain advanced automation systems effectively.

- Cybersecurity Risks: Connected industrial systems must be safeguarded against potential cyber threats.

By understanding these challenges, businesses can plan effectively, mitigate risks, and maximize the ROI from GE Automation & Controls.

What Industries Commonly Use GE Automation & Controls?

GE Automation & Controls serves a wide range of industries where precision, efficiency, and reliability are critical. By integrating advanced automation technologies, these solutions help businesses optimize operations, reduce costs, and improve safety. The following industries are among the primary users of GE’s automation and control systems:

- Manufacturing and manufacturing: GE Automation & Controls provides solutions to automate production lines, helping to reduce manual labor and increase precision in assembly and product inspection processes.

- Energy and electricity: In the energy sector, GE Automation & Controls plays an important role in managing and optimizing the power grid. This system supports power plants to operate more efficiently through precise monitoring and control capabilities, ensuring a stable and safe supply of energy.

- Oil and gas: GE Automation & Controls is the leading choice in the oil and gas industry with the ability to control and monitor oil and gas extraction and transportation systems. These solutions not only improve operational efficiency but also increase the safety of employees and equipment, reducing the risk of incidents during operation.

- Logistics and transportation: GE Automation & Controls supports supply chain optimization through automating warehouse management. Smart systems help reduce inventory errors, improve inventory management efficiency and reduce order processing time.

GE Automation & Controls serves a wide range of industries

Conclusion

In conclusion, GE Automation & Controls provides powerful solutions that help industries enhance productivity, improve process reliability, and achieve operational excellence. From streamlining complex manufacturing operations to enabling smarter decision-making, these technologies play a crucial role in modern industrial automation.

At Flextech, we bring expertise in implementing advanced automation and control solutions, including GE systems, tailored to the specific needs of your business. Our team ensures seamless integration, optimized performance, and ongoing support, helping your operations stay efficient, competitive, and future-ready.