OPC UA (Open Platform Communications Unified Architecture) is a modern, service-oriented protocol designed to unify communication among diverse industrial systems. It is platform-independent, ensuring interoperability between equipment and software from different vendors.

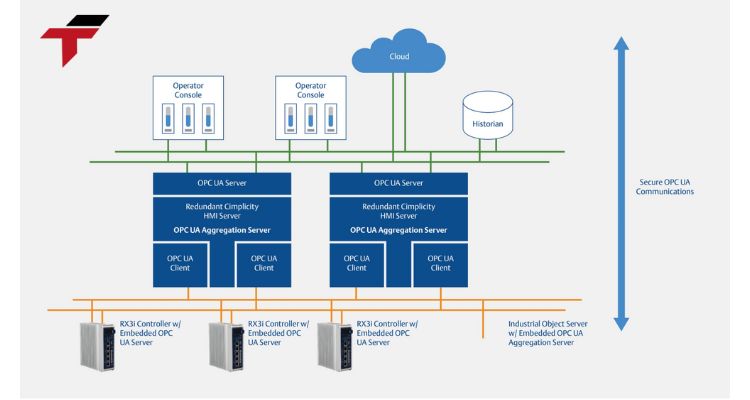

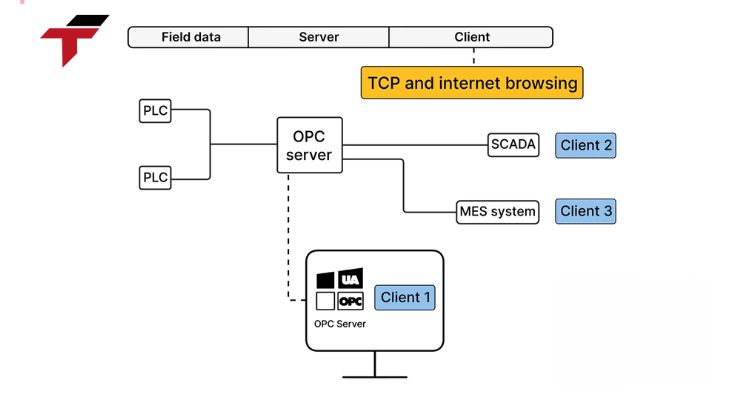

When integrated into HMI (Human Machine Interface) systems, OPC UA acts as a secure bridge for real-time data sharing between PLCs, SCADA, MES, and even cloud platforms. This integration plays a crucial role in creating connected, intelligent, and responsive manufacturing environments, a key milestone toward Industry 4.0 automation goals.

What Benefits Does OPC UA Bring to HMI Integration?

Integrating OPC UA into HMI systems provides numerous operational and technical advantages that transform traditional automation setups into intelligent ecosystems:

- Seamless Interoperability: As a vendor-neutral standard, OPC UA enables HMIs to exchange data across different brands of PLCs and devices without needing custom drivers or gateways.

- Enhanced Security: Built-in encryption, authentication, and user control protect communication from unauthorized access and cyber threats.

Scalable Architecture: Whether used for a single machine or an enterprise-wide SCADA network, OPC UA scales easily from on-premises systems to cloud-integrated platforms. - Advanced Data Modeling: OPC UA supports complex data structures, allowing HMIs to process contextual and structured data instead of basic tag-level communication.

What Benefits Does OPC UA Bring to HMI Integration?

Which Devices Can Communicate Through OPC UA?

The key strength of OPC UA lies in its versatility and wide compatibility with industrial hardware and software. Devices commonly supporting or benefiting from OPC UA include:

- PLCs: Modern controllers such as Siemens S7-1500, Allen-Bradley ControlLogix, and Beckhoff TwinCAT natively support OPC UA communication.

- SCADA & MES Systems: These platforms use OPC UA to collect and visualize data from HMIs and PLCs for plant-wide control.

- Industrial PCs & Edge Gateways: These serve as OPC UA clients or servers to pre-process and transmit data to higher systems or the cloud.

- Cloud Platforms & IIoT Solutions: Services like AWS IoT, Azure IoT, and Siemens MindSphere connect to OPC UA sources for analytics, AI, and remote monitoring.

- Smart Sensors & Actuators: With embedded OPC UA servers, they can directly interact with controllers and HMIs without intermediary systems.

Robots & CNC Machines: OPC UA enables real-time machine coordination, diagnostics, and maintenance communication.

This broad compatibility demonstrates how OPC UA unifies various components of modern industrial networks.

Where Is OPC UA HMI Integration Commonly Applied?

OPC UA-based HMI systems are now widely adopted across multiple industrial sectors due to their efficiency and standardization:

- Automotive Manufacturing: Enables seamless coordination between robots, PLCs, and quality systems for consistent production quality.

Food and Beverage: Ensures batch traceability and hygiene monitoring through real-time integration of processing and packaging equipment. - Pharmaceuticals: Supports GMP and FDA compliance by ensuring secure and traceable machine data logging.

- Oil & Gas: Provides safe, remote access and control over geographically distributed assets via SCADA-HMI integration.

- Water & Wastewater Treatment: Facilitates centralized monitoring of tanks, pumps, and flow systems across treatment plants.

- Smart Buildings & Energy Systems: Allows building management systems to communicate with HVAC and lighting control through OPC UA-connected HMI dashboards.

Where Is OPC UA HMI Integration Commonly Applied?

How Does OPC UA Differ from Classic OPC?

While both OPC and OPC UA aim to enable communication between automation devices, OPC UA offers significant advancements:

| Feature | Classic OPC | OPC UA |

| Security | Basic or limited | Strong encryption and user authentication |

| Communication Protocol | Based on DCOM | Uses TCP/IP, HTTPS, and MQTT |

| Cloud Compatibility | Not designed for IIoT | Fully cloud- and IoT-ready |

| Data Modeling | Simple tags | Complex data structures and semantics |

In short, OPC UA is the evolution of Classic OPC, delivering enhanced security, flexibility, and scalability suited for Industry 4.0 environments.

What Are the Emerging OPC UA Trends for 2025?

As the digital transformation of manufacturing accelerates, OPC UA continues to evolve. Key trends shaping 2025 include:

- Integration with AI and Predictive Maintenance: Machine data from OPC UA networks powers AI tools to forecast failures and improve uptime.

- Adoption of OPC UA FX (Field eXchange): This extension allows field-level devices such as drives and sensors to communicate natively using OPC UA.

- Stronger Cloud Connectivity: Modern cloud services now natively support OPC UA, enabling direct data flow from machines to digital twins and analytics systems.

- Cybersecurity Reinforcement: Organizations are adopting security-first OPC UA configurations, including certificate management and encrypted sessions, to protect against modern threats.

Why Is OPC UA Integration Crucial for the Future of Automation?

Integrating OPC UA with HMI systems is not merely a technical enhancement. It is a strategic investment in digital transformation.

By adopting OPC UA, manufacturers achieve:

- True interoperability across heterogeneous devices,

- Secure, encrypted communication,

- Efficient data exchange from edge to cloud, and

- Scalable, future-ready automation architecture.

As industries continue to evolve toward smart manufacturing, OPC UA HMI integration stands at the core of intelligent, connected, and data-driven operations – paving the way for the next generation of industrial innovation.