Human-Machine Interfaces (HMIs) are the backbone of modern industrial automation, providing operators with real-time control and monitoring of machinery. However, the efficiency and reliability of HMIs heavily depend on the communication protocols they use. Understanding HMI Protocols: Modbus, OPC UA, Profibus is essential for manufacturers in Malaysia aiming to improve connectivity, streamline operations, and support Industry 4.0 initiatives. Choosing the right protocol ensures seamless integration between HMIs, Programmable Logic Controllers (PLCs), and other automation devices.

What Are HMI Protocols?

HMI protocols are standardized communication methods that allow HMIs to interact with PLCs, sensors, and other industrial devices. They define how data is exchanged, ensuring that devices from different manufacturers can communicate effectively.

Choosing the correct HMI protocol affects performance, network reliability, and security. In Malaysia’s industrial sector, spanning palm oil mills, F&B processing, automotive, and electronics, selecting the right protocol can significantly improve monitoring efficiency and reduce downtime.

What Are HMI Protocols?

Overview of Key HMI Protocols

The three most widely used HMI protocols, Modbus, OPC UA, and Profibus, each offer unique advantages for industrial applications. Understanding their features and applications helps Malaysian manufacturers select the right protocol for their operations.

1. Modbus

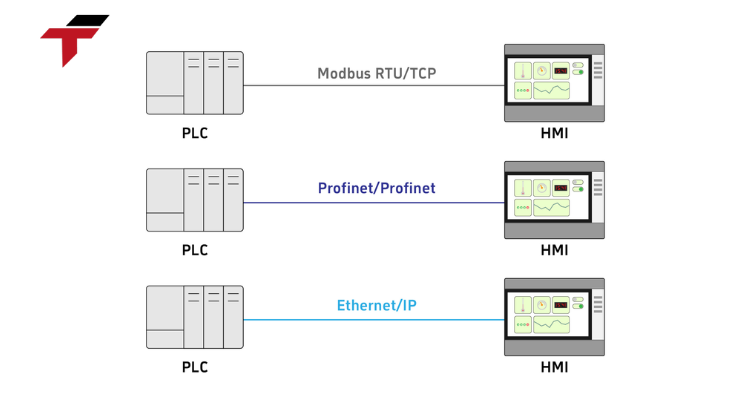

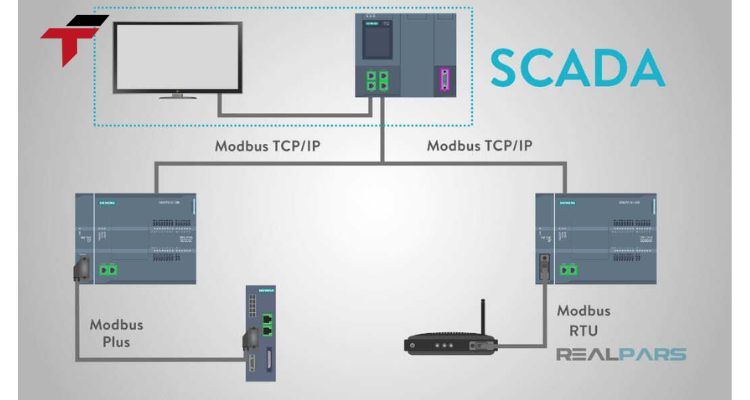

Modbus is one of the most widely used HMI protocols worldwide, known for its simplicity and compatibility. It comes in two main variants:

- Modbus RTU: Serial communication using RS-485, ideal for simple, cost-effective applications.

- Modbus TCP/IP: Ethernet-based, allowing faster data transfer and remote connectivity.

Features & Benefits:

- Easy to implement and widely supported

- Compatible with most PLCs and industrial devices

- Reliable for small to medium-sized factories

Common Applications in Malaysia:

- Factory assembly lines

- Water treatment systems

- Basic process automation in food and beverage plants

Modbus – Flextech

2. OPC UA (Open Platform Communications Unified Architecture)

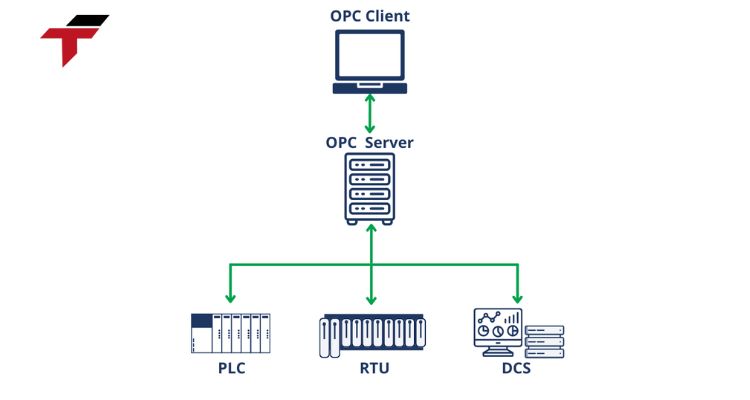

OPC UA represents a modern approach to HMI communication, providing a secure and platform-independent protocol ideal for IIoT-enabled factories and complex automation systems. OPC UA is a modern, secure, and platform-independent protocol designed for IIoT-ready industrial networks.

Features & Benefits:

- Supports real-time and historical data exchange

- Highly secure with encryption and authentication

- Platform-independent, suitable for diverse systems

Common Applications in Industry:

- Smart factories with IIoT integration

- Remote monitoring of industrial plants

- Data analytics and predictive maintenance

OPC UA – Flextech

3. Profibus

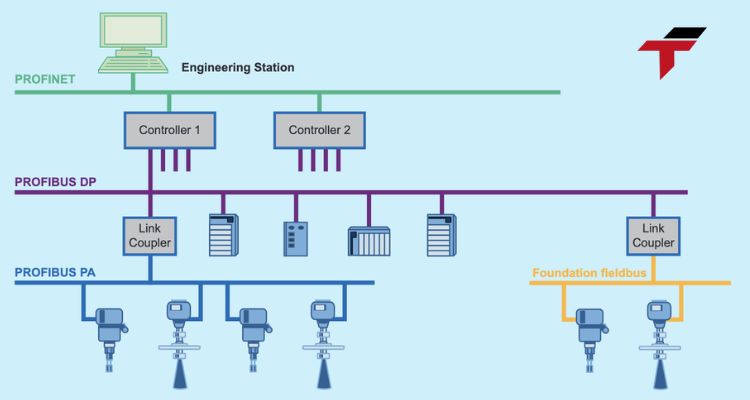

Profibus is a high-performance fieldbus protocol commonly used in process-heavy industries. It excels in reliability and speed, making it suitable for critical automation systems. Profibus (Process Field Bus) is a fieldbus protocol widely used in process automation for its high reliability and fast communication.

Types:

- Profibus DP (Decentralized Peripherals): Optimized for fast communication with sensors and actuators.

- Profibus PA (Process Automation): Designed for process industry applications with intrinsic safety support.

Features & Benefits:

- Real-time data transfer

- High reliability for critical processes

- Supports large industrial networks

Common Applications:

- Palm oil mills and chemical plants

- Automotive and electronics assembly lines

- Continuous production processes require high reliability

Profibus – Flextech

Comparison Table: Modbus vs OPC UA vs Profibus

Compare Modbus, OPC UA, and Profibus to understand their speed, security, and scalability. This guide helps industries choose the right HMI protocol for efficient automation systems.

| Feature | Modbus | OPC UA | Profibus |

| Communication Type | Serial / TCP | TCP/IP | Fieldbus |

| Security | Basic | High (Encryption & Auth) | Moderate |

| Speed | Moderate | High | High |

| Scalability | Medium | High | High |

| Use Case | Small factories | Smart factories, IIoT | Process automation |

How to Choose the Right HMI Protocol

Selecting the right protocol can be challenging. Consider factors like device compatibility, network size, data speed, security, and IIoT readiness to ensure seamless operations.

Selecting the right protocol depends on several factors:

- Device Compatibility: Ensure HMIs and PLCs support the protocol.

- Network Size: Large factories may require OPC UA or Profibus for scalability.

- Data Speed Requirements: High-speed processes benefit from Profibus or OPC UA.

- Security Needs: OPC UA offers the highest security for sensitive data.

- IIoT Readiness: OPC UA integrates seamlessly with IIoT platforms.

How Are HMI Protocols Applied Across Industries

HMI protocols are applied differently depending on the industry. Malaysian factories use Modbus, OPC UA, and Profibus to meet specific operational needs, from batch processes to high-speed automation.

- F&B Manufacturing: OPC UA is ideal for batch process control and remote monitoring.

- Palm Oil Mills: Profibus ensures reliable process control in large-scale production.

- Automotive & Electronics: Modbus supports assembly line HMIs and PLCs.

- Cold Storage & Logistics: OPC UA integrates sensors, conveyors, and warehouse HMIs.

- General Factories: Combining Modbus and Profibus supports diverse legacy and modern equipment.

Benefits of Using Proper HMI Protocols

Choosing the right HMI protocol offers tangible benefits, including higher efficiency, better data accuracy, and enhanced system security for Malaysian manufacturers.

- Enhanced Data Accuracy: Real-time monitoring ensures reliable operations.

- Improved Interoperability: Seamless communication across devices from different manufacturers.

- Increased Security: Especially with OPC UA, data encryption protects against cyber threats.

- Reduced Downtime: Efficient monitoring and predictive maintenance minimize production stoppages.

- Statistic Example: Factories using OPC UA reported up to 30% faster data processing for monitoring systems (OPC Foundation).

Best Practices & Implementation Tips

Implementing HMI protocols effectively requires careful planning. Following best practices ensures optimal performance and avoids common pitfalls.

- Verify Device Compatibility: Check PLC and HMI support before protocol selection.

- Optimize Network Design: Minimize latency and prevent congestion.

- Plan for Scalability: Ensure protocols can support future IIoT expansion.

- Maintain Security: Update firmware and software regularly.

- Avoid Common Mistakes: Prevent mismatched baud rates, device incompatibility, and improper wiring.

Conclusion

Understanding the differences and applications of Modbus, OPC UA, and Profibus allows Malaysian manufacturers to make informed decisions about HMI protocol selection.

Choosing the right HMI protocol Modbus, OPC UA, or Profibus—is crucial for Malaysian manufacturers seeking efficient, secure, and scalable automation systems. While Modbus remains ideal for smaller, legacy setups, OPC UA provides a modern, secure solution for IIoT-enabled smart factories. Profibus continues to excel in process-heavy industries like palm oil and automotive production. By understanding the features, applications, and best practices of each protocol, industrial decision-makers can ensure seamless HMI-PLC communication, reduce downtime, and maximize operational efficiency.

FAQs

Q1: Which HMI protocol is best for small vs large factories?

A1: Modbus is suitable for small factories, while OPC UA or Profibus is better for large, scalable operations.

Q2: Can Modbus and OPC UA work together?

A2: Yes, hybrid networks often combine Modbus for legacy devices and OPC UA for modern IIoT integration.

Q3: How secure are these protocols in Malaysian industrial networks?

A3: OPC UA offers the highest security with encryption and authentication, Modbus is less secure but widely used, and Profibus has moderate security for industrial environments.