The Human–Machine Interface (HMI) is a critical component in Malaysia’s push towards digital manufacturing under the Industry4WRD initiative. It serves as the operator’s window into complex industrial processes, transforming raw machine data into actionable, visual information.

What Is an HMI?

A Human-Machine Interface (HMI) is an application or device that presents process data to a human operator and, through a graphical interface, allows the operator to control and monitor the industrial process.

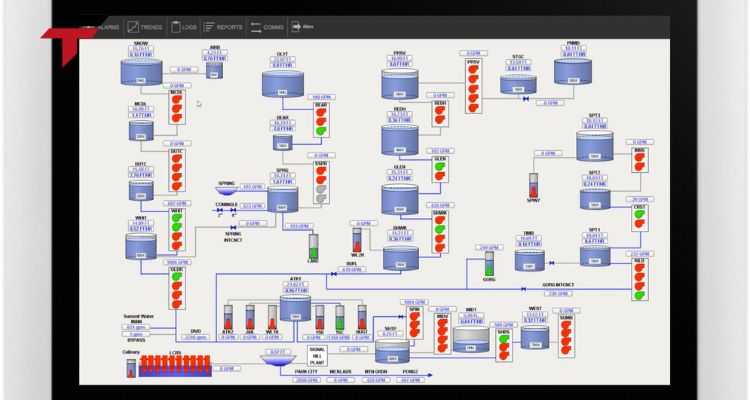

In industrial control systems, the HMI’s primary role is real-time visualization of equipment status, production metrics, and alarm conditions. It is the crucial bridge between human workers and the sophisticated machinery, Programmable Logic Controllers (PLCs), and control systems driving modern factories.

What Is an HMI?

Key Components of an HMI System

An HMI system typically consists of integrated hardware and software elements designed for reliable industrial use:

- Display/Screen: Most modern HMIs utilize an industrial display with a touch panel for direct, intuitive control input. These vary in size, resolution, and ruggedness.

- Processor & Memory (CPU/RAM): The core hardware that runs the HMI software, processes data, and renders the graphics.

- Communication Ports: Essential for connectivity, these ports (e.g., Ethernet, RS-232, RS-485) enable PLC integration and communication with other field devices.

- Operating Software: The configuration software used to design the graphical screens, map data tags, and define the HMI’s functionality.

How HMI Works With PLCs, SCADA, Sensors, and Field Devices

The HMI functions as a communication hub and display terminal within the automation architecture:

- Data Acquisition: It establishes a connection (via its communication ports) to PLCs, sensors, and other field devices.

- Protocol Communication: It uses standard industrial protocols (like Modbus TCP/IP or OPC UA) for PLC communication to read and write data.

- I/O Mapping: It maps PLC memory addresses (data registers) to internal HMI tags. These tags represent the physical I/O status (e.g., motor running, temperature reading).

- Visualization: The HMI software uses these tags to update objects on the screen in real-time, such as changing a pump’s color when it is running or displaying a live temperature value.

- SCADA Connection: HMIs often act as local operator stations that connect to a larger SCADA system (Supervisory Control and Data Acquisition) for system-wide monitoring and data historization.

How HMI Works With PLCs, SCADA, Sensors, and Field Devices

Types of HMIs Used in Malaysian Industries

The Malaysian industrial landscape employs various HMI types, each suited for different applications and environments.

Basic HMI Panels vs. Advanced Touchscreen HMIs

| Feature | Basic HMI Panels | Advanced Touchscreen HMIs |

| Typical Use | Simple machine control, single-function display, and equipment setup. | Complex process visualization, recipe management, data trending, and connectivity. |

| Display | Smaller screen sizes (4″–7″), lower resolution, often monochromatic or basic colour. | Larger screens (7″ to 21″+), high resolution, full-colour graphics. |

| Connectivity | Limited protocols, fewer communication ports. | Extensive protocol support (Ethernet/IP, OPC UA, etc.), more connectivity options. |

PC-Based HMI, Web-Based HMI, Cloud-Enabled HMI

- PC-Based HMI: Runs on an industrial PC HMI using standard PC operating systems (like Windows). This offers superior processing power, massive storage capacity, and the flexibility to run other applications alongside the HMI software. Ideal for complex SCADA-level visualizations.

- Web-Based HMI: Uses a browser-based HMI design, allowing operators to view and control the process through a standard web browser (on a PC, tablet, or mobile). This drastically simplifies deployment and enables internal remote access.

- Cloud-Enabled HMI: Connects directly to the cloud, facilitating remote visualization, secure data storage, and integration with advanced analytics platforms as part of an IIoT (Industrial Internet of Things) strategy.

Rugged HMIs for Harsh Environments (F&B, Palm Oil, Manufacturing)

Malaysian industries like Palm Oil Mills and F&B Manufacturing require HMIs designed to withstand challenging conditions:

- IP-rated HMI: Rated for protection against dust and water ingress (e.g., IP65, IP67).

- Stainless-steel HMI: Essential in washdown environments where equipment is regularly cleaned with high-pressure jets and caustic chemicals to maintain HACCP compliance.

- Wide Temperature Range: Built to operate reliably in high ambient temperatures typical of tropical manufacturing plants.

Core Features and Functional Capabilities of HMI Systems

The power of an HMI lies in its functionality, which extends far beyond simple display.

- Real-Time Monitoring & Visualisation: The core function is providing live machine status and process feedback. Operators rely on factory dashboards to view critical parameters (e.g., tank levels, flow rates, cycle times) using animated graphics, meters, and gauges, facilitating rapid and informed decision-making for efficient production monitoring.

- Alarm Management, Notifications & Event Tracking: HMIs are crucial for safety and efficiency through robust alarm management. They constantly monitor process values against predefined limits, instantly displaying operator alerts and detailed error messages when anomalies occur. The HMI logs every change of state and alarm into an alarm history database for later analysis.

- Data Logging, Historian & Reporting: HMIs are increasingly used as a localised data historian or gateway. They collect time-stamped operational data, which is then used to generate production reports, perform downtime analysis, and feed into high-level machine analytics for Overall Equipment Effectiveness (OEE) calculations.

- Remote Access & Mobility for Industry 4.0: For supervisors and maintenance teams, remote HMI access via virtual network computing (VNC) or specialized mobile HMI apps is essential. This capability supports the Industry 4.0 trend by allowing personnel to safely monitor and troubleshoot equipment from anywhere, ensuring rapid response and minimal downtime.

Core Features and Functional Capabilities of HMI Systems

How HMI Keeps Automation Connected

Connectivity is the lifeline of the HMI, enabling seamless data flow across the automation ecosystem.

Common Protocols: Modbus, OPC UA, Profibus, Profinet, Ethernet/IP

Modern HMIs must support a wide array of industrial communication protocols to achieve protocol compatibility with different vendor equipment:

- Modbus (TCP/IP & RTU): Still widely used in Malaysia due to its simplicity and universality.

- OPC UA: The de facto standard for secure, reliable, vendor-independent data exchange in the Industry 4.0 era.

- Vendor-Specific Protocols: Such as Profinet and Ethernet/IP (used by Siemens and Allen-Bradley, respectively) and Profibus, are crucial for deep integration with specific PLC ecosystems.

HMI Tagging System – Mapping PLC Variables to Interface Displays

The HMI tagging system is the mechanism that links the PLC’s internal memory addresses to the graphical objects on the HMI screen. Each HMI tag defines a specific data point (e.g., temperature setpoint, motor speed, batch status) and its corresponding PLC memory address. Effective data mapping is vital for the HMI to accurately reflect the process state and execute control commands.

HMI Applications Across Key Industries

HMIs are indispensable tools tailored for the unique challenges of Malaysian industrial sectors.

F&B Manufacturing: Quality Control, Packaging, Batch Processes

In food automation, HMIs facilitate:

- Recipe Management: Quick selection and loading of different product recipes (e.g., mixing ratios, cooking temperatures).

- Quality Control: Monitoring critical values for HACCP compliance, such as sterilisation temperature and metal detector status.

- Packaging HMI: Controlling high-speed fillers, sealers, and labelers.

Palm Oil Mills: Process Monitoring, Temperature/Pressure Control

The robust environment of palm oil mills requires rugged HMIs for:

- Process Monitoring: Visualizing the entire process flow from receiving to extraction.

- Steriliser Control: Precise monitoring and control of temperature/pressure control for the sterilisation cycle to ensure mill efficiency and oil quality.

Automotive & Electronics: Robotics, Assembly Line Monitoring

In high-speed assembly automation:

- Robotic HMI: Providing teach pendants and control panels for managing and troubleshooting industrial robots.

- Line Balancing: Monitoring cycle times and overall throughput to maintain maximum efficiency and product quality.

Cold Storage & Logistics: Conveyor Systems, ASRS, Warehouse Monitoring

HMIs manage the flow and temperature-sensitive operations in logistics:

- Cold Room Monitoring: Displaying and logging temperature and humidity for compliance.

- Conveyor HMI: Controlling and visualizing the status of complex conveyor systems and sorters.

- ASRS Integration: Providing an interface for the automated storage and retrieval system (ASRS overview).

HMI Applications Across Key Industries

Conclusion

The Human-Machine Interface (HMI) is far more than a simple screen. It is the cognitive center of industrial automation, especially vital in Malaysia’s modernizing manufacturing landscape. By bridging the physical control layer with the digital information layer, HMIs enable the high levels of efficiency, data transparency, and connectivity required to fulfill the vision of Industry 4.0.