Limit switches are essential devices in industrial automation, ensuring machine safety, precise control, and reliable operation in Malaysia’s manufacturing sector. They detect positions, control movement, and prevent mechanical errors.

What Is a Limit Switch?

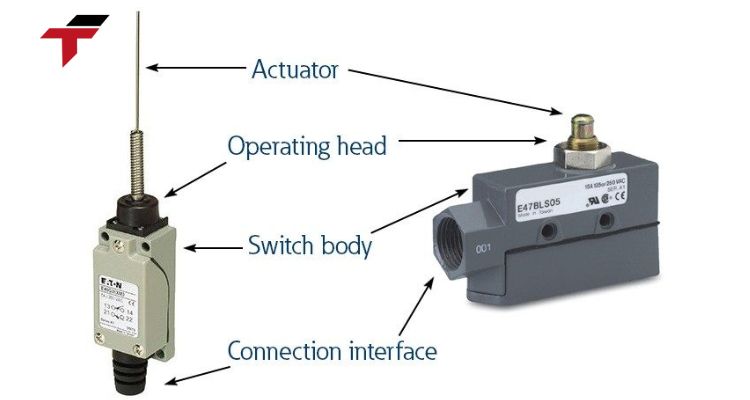

A limit switch is an electromechanical device used to detect the position or movement of an object, sending signals to control machine operations and ensure safety. It works through a physical actuator that is pressed by the moving object, triggering internal contacts to open or close an electrical circuit. Highly durable, limit switches are designed to operate reliably in harsh industrial environments, resisting dust, moisture, vibration, and extreme temperatures, making them essential for automated systems in factories.

What Is a Limit Switch?

How a Limit Switch Works

Limit switches operate through a simple mechanical mechanism, where an actuator movement triggers electrical contacts to control machine functions accurately and safely.

- Actuator movement triggers switch: Objects press the actuator (roller, plunger, rod), causing mechanical contact inside.

- Contacts open or close circuits: The internal contacts respond to actuator movement, sending a signal to start, stop, or reverse equipment.

- Robust and consistent operation: The mechanical design ensures repeated reliable performance, even in demanding automation setups.

Different Types of Limit Switches for Industrial Automation

Various limit switch designs exist to suit different applications, including mechanical and environmental requirements, ensuring precise detection and long-term performance.

- Roller lever switch: Uses a rotating roller to detect movement, commonly applied in conveyor and packaging systems.

- Plunger/push-type switch: Provides precise detection, ideal for cams or small mechanical movements in machines.

- Rod/whisker switch: Detects irregular surfaces or objects, useful in logistics and material handling.

- Micro limit switch: Compact, sensitive, suitable for small equipment requiring precise actuation.

- Waterproof/heavy-duty switch: IP65–IP67 rated switches are ideal for dusty, wet, or outdoor industrial environments.

Different Types of Limit Switches for Industrial Automation

How Limit Switches Are Used in Industries

Limit switches are widely used in Malaysia’s manufacturing and automation sectors to control machines, improve safety, and enhance productivity across various industries.

- Conveyor and material handling: Detect end positions, control motor stops, and count items efficiently on production lines.

- Manufacturing and assembly: Ensures travel limits, machine safety, and precise mechanical movement verification.

- Warehouse automation: Used in stacker cranes, shuttle systems, and automated storage equipment for accurate positioning.

- Packaging and food processing: Monitors machine doors, controls sealing/cutting, and prevents product jams.

Key Advantages of Using Limit Switches in Automation

Limit switches provide reliable, cost-effective, and durable solutions for precise position detection and machine safety in industrial automation systems.

- High reliability: Their simple mechanical design ensures consistent operation over millions of cycles.

- Cost-effective solution: Limit switches are generally less expensive than sensors while offering accurate detection.

- Durability in harsh environments: Resistant to dust, vibration, moisture, and extreme temperatures.

- Precise detection: Ideal for verifying exact machine limits or safety stops.

- Long service life: Mechanical components and robust housing provide years of operation without frequent replacement.

Key Advantages of Using Limit Switches in Automation

Limit Switch vs. Proximity Sensor

Understanding the key differences between limit switches and proximity sensors helps engineers select the right device for precise mechanical detection or non-contact sensing in industrial automation systems.

| Feature | Limit Switch | Proximity Sensor |

| Detection Method | Requires physical contact through an actuator | Uses magnetic, optical, or capacitive sensing without contact |

| Durability | Performs reliably in harsh industrial conditions | Sensitive to dust, vibration, or environmental factors |

| Cost Comparison | Generally more affordable | Can be costlier depending on technology type |

| Application Suitability | Ideal for mechanical travel limits and safety stops | Suitable for non-contact presence detection and object sensing |

How to Choose the Right Limit Switch

Selecting the proper limit switch ensures reliable performance, correct actuation, and long-term durability in Malaysia’s industrial automation systems.

- Application type: Choose actuator style according to object type: roller lever for conveyors, plunger for cams, whisker for irregular surfaces.

- Electrical ratings: Confirm voltage and current match the automation system’s specifications.

- IP protection: Select IP65 for dry areas and IP67 for wet or dusty environments.

- Mechanical durability: Check actuator strength, housing material, and cycle rating.

- Mounting requirements: Ensure the switch can be securely mounted to avoid misalignment or vibration errors.

How to Properly Install a Limit Switch

Proper installation ensures limit switches function correctly, avoid premature wear, and maintain safety in industrial automation systems.

- Align actuator with object: Correct positioning prevents missed detection or false triggers.

- Avoid excessive force: Prevents damage to the actuator and internal contacts.

- Use proper wiring: Shielded or industrial-grade cables prevent electrical noise interference.

- Seal in wet areas: Proper gaskets and housing prevent water or dust ingress.

Test before operation: Confirm actuation distance and switch reset movement during commissioning.

How Do You Troubleshoot a Limit Switch?

Regular inspection and troubleshooting prevent failures, ensuring limit switches remain reliable in industrial automation systems.

- Misalignment: Adjust the actuator position to ensure proper contact.

- Mechanical wear: Replace worn actuators or springs to maintain function.

- Electrical failure: Verify voltage/current ratings and replace burned contacts if necessary.

- Loose mounting: Tighten screws or brackets to prevent vibration-related errors.