PID control is essential for precise and stable industrial processes. By continuously adjusting system outputs based on feedback, it improves efficiency, reduces errors, and ensures consistent quality. Discover how Flextech helps businesses implement PID systems effectively for smarter operations.

What Is PID Control?

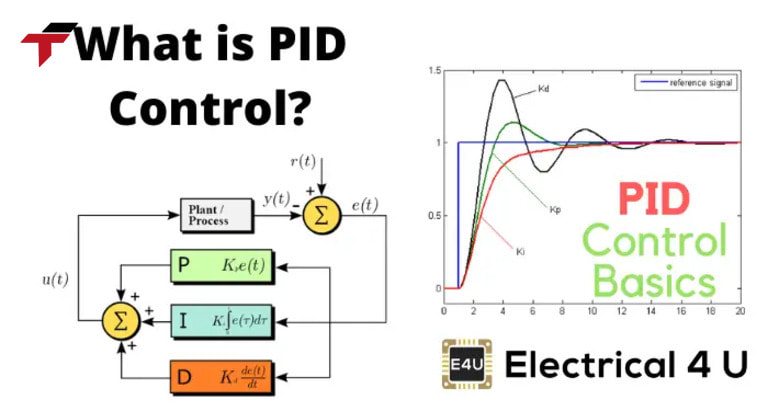

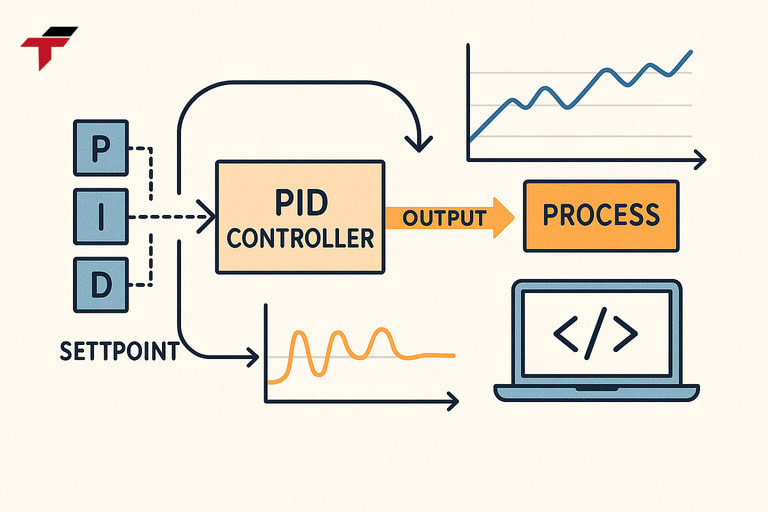

PID Control, which stands for Proportional-Integral-Derivative Control, is one of the most widely used feedback control methods in industrial automation and process control. It is designed to automatically regulate variables such as temperature, pressure, flow, or speed to maintain a desired setpoint in a system.

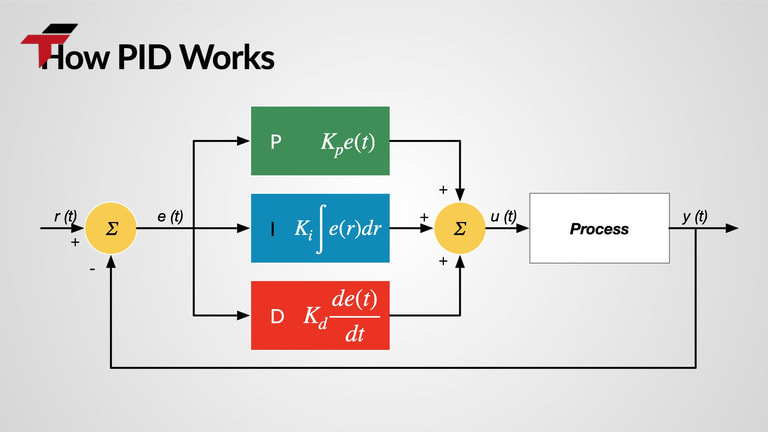

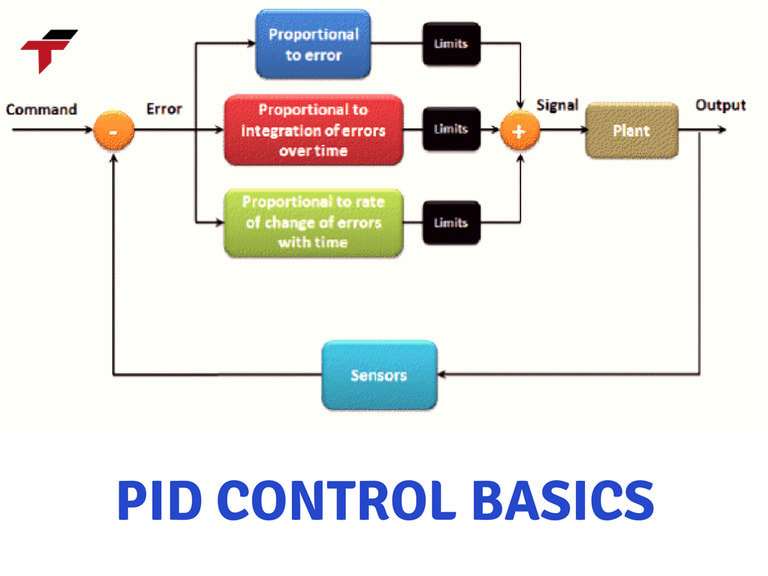

A PID controller continuously calculates the difference between the desired setpoint and the measured process variable (known as the error) and applies corrective actions based on three components:

- Proportional (P): Responds proportionally to the current error, providing immediate corrective action.

Integral (I): Accounts for the accumulation of past errors to eliminate steady-state offsets.

Derivative (D): Predicts future errors based on the rate of change, helping to reduce overshoot and improve system stability.

By combining these three elements, PID control achieves precise, stable, and reliable control of industrial processes. It is versatile, applicable across a wide range of industries including manufacturing, energy, robotics, and chemical processing, making it a cornerstone of modern automation systems.

PID Control, which stands for Proportional-Integral-Derivative Control

How Does PID Control Work?

PID control works as a feedback loop, continuously monitoring a process variable and adjusting the output to minimize error. The process can be broken down into 7 steps:

- Step 1: Measure the Process Variable: The system uses sensors to measure the current value of the variable being controlled (e.g., temperature, pressure, or flow rate).

- Step 2: Calculate the Error: The controller computes the difference between the desired setpoint and the measured value. This difference is called the error.

- Step 3: Apply Proportional Action (P): The proportional component generates a corrective output based on the magnitude of the current error. Larger errors produce larger corrections.

- Step 4: Apply Integral Action (I): The integral component considers the sum of past errors over time, addressing any steady-state offset and ensuring the process reaches the setpoint accurately.

- Step 5: Apply Derivative Action (D): The derivative component predicts future errors by evaluating the rate of change of the error, helping to reduce overshoot and improve system stability.

- Step 6: Combine PID Outputs and Adjust Control Device: The outputs from P, I, and D are combined into a single control signal, which adjusts the actuator (e.g., valve, motor, heater) to bring the process variable closer to the setpoint.

- Step 7: Continuous Feedback and Adjustment: This process repeats continuously, forming a closed-loop system that maintains optimal control despite disturbances or changes in the process.

PID control operates as a continuous feedback loop, combining proportional, integral, and derivative actions to precisely regulate industrial processes. By measuring the process variable, calculating errors, and adjusting outputs in real time, PID ensures stability, accuracy, and responsiveness across various applications.

The process can be broken down into 7 steps

What Are the Advantages and Disadvantages of PID Controllers?

PID controllers are one of the most widely used tools in industrial automation due to their ability to maintain precise and stable control over a wide range of processes. However, like any control system, they come with both strengths and limitations. Understanding the advantages and disadvantages of PID controllers helps engineers and businesses implement them effectively.

Advantages of PID Controllers

PID controllers are widely used in industrial automation because they provide precise and reliable control over a variety of processes. Their advantages make them indispensable in achieving high performance and efficiency across industries. 6 benefits include:

- High Accuracy and Stability: PID controllers continuously monitor the process and adjust outputs to keep variables close to the desired setpoint, reducing fluctuations and ensuring stable operation.

- Versatility Across Industries: From manufacturing and robotics to energy and chemical processing, PID controllers can be applied to control temperature, pressure, flow, speed, and other critical variables.

- Enhanced Efficiency: By optimizing process control, PID reduces energy consumption, material waste, and operational downtime, contributing to overall cost savings.

- Fast Response to Disturbances: The proportional and derivative components allow the system to quickly react to sudden changes or unexpected disturbances, maintaining consistent process performance.

- Elimination of Steady-State Error: The integral component corrects accumulated errors over time, ensuring long-term precision and reliability.

- Wide Availability and Support: PID controllers are well-established in the automation industry, compatible with PLCs, DCS, and SCADA systems, making them easy to integrate and maintain.

Disadvantages of PID Controllers

While PID controllers offer significant benefits, they also come with limitations that need to be considered for effective implementation. 3 key disadvantages include:

- Complex Tuning Requirements: Determining the optimal values for proportional, integral, and derivative parameters can be challenging and may require trial-and-error or specialized software tools.

- Sensitivity to Noise: The derivative component can amplify high-frequency noise from sensors, which may destabilize the system if not properly filtered.

Limited Performance in Nonlinear or Time-Varying Systems: PID controllers are most effective in linear systems. Performance can degrade when applied to highly nonlinear or rapidly changing processes.

Advantages and Disadvantages of PID Controllers

What are the key differences between PLC and PID controllers?

PID controllers and PLCs (Programmable Logic Controllers) are both essential tools in industrial automation, but they serve different purposes and operate in distinct ways. Understanding their key differences helps businesses and engineers choose the right solution for controlling processes and machinery.

| PLC (Programmable Logic Controller) | PID Controller | |

| Primary Function | Executes logic-based control programs to manage machines, devices, and processes. | Maintains precise control of a process variable (e.g., temperature, pressure, flow) by minimizing the difference between setpoint and actual value. |

| Control Method | Logic-based, discrete on/off control; can include timers, counters, and sequential operations. | Continuous feedback control using Proportional, Integral, and Derivative calculations. |

| Application Scope | Broad applications including machinery automation, conveyor systems, robotics, and I/O monitoring. | Specialized process control for variables like temperature, speed, pressure, or flow in chemical, manufacturing, and energy systems. |

| Complexity | Can handle complex sequences, multiple devices, and integrated logic operations. | Focuses on precise control of one or a few process variables. |

| Integration | Can integrate with multiple devices, networks, and even PID loops; programmable for varied industrial tasks. | Often implemented as part of a PLC or DCS system; controls a single process loop or variable. |

| User Expertise | Requires knowledge of PLC programming languages like Ladder Logic, Structured Text, or Function Block Diagram. | Requires knowledge of PID tuning methods and process dynamics for optimal performance. |

What Are the Challenges and Limitations of PID Control?

While PID control is a cornerstone of industrial automation, it comes with certain challenges and limitations that engineers and businesses must understand to ensure effective implementation:

- Complex Tuning Requirements: Achieving optimal PID performance requires carefully setting the proportional, integral, and derivative parameters. Incorrect tuning can lead to system instability, overshoot, or slow response.

- Sensitivity to Noise: The derivative component is particularly sensitive to high-frequency noise from sensors, which can amplify fluctuations and reduce control accuracy if not properly filtered.

- Limited Effectiveness in Nonlinear Systems: PID controllers are most effective in linear, time-invariant systems. Highly nonlinear, time-varying, or complex multi-variable processes may require advanced control strategies.

- Potential for Oscillations: Poorly tuned PID parameters can cause continuous oscillations or even instability in the controlled system, affecting product quality and safety.

- Dependency on Process Knowledge: Effective PID control requires a solid understanding of the process dynamics, system delays, and external disturbances. Inadequate knowledge can result in suboptimal performance.

Challenges and Limitations of PID Control

How Does PID Control Integrate with Modern Automation Systems?

PID controllers are widely used in modern automation systems due to their reliability, precision, and flexibility. They can be integrated with various industrial control architectures to optimize process performance and support advanced manufacturing strategies. Here’s how PID control fits into modern automation systems:

- Integration with PLCs (Programmable Logic Controllers): PID loops are often embedded within PLC programs, allowing precise control of temperature, pressure, flow, or speed while maintaining the broader logic and sequence control provided by the PLC.

- Connection with DCS (Distributed Control Systems): In large-scale industrial plants, PID controllers are integrated into DCS platforms. This allows centralized monitoring, multi-loop coordination, and advanced process management for complex processes like chemical production, power generation, or oil refining.

- Communication with SCADA Systems: PID controllers can feed real-time process data into SCADA (Supervisory Control and Data Acquisition) systems. Operators can monitor process variables, adjust setpoints, and receive alerts remotely, enhancing operational visibility and decision-making.

By integrating PID controllers with PLCs, DCS, SCADA, IIoT platforms, and HMIs, modern automation systems achieve enhanced precision, real-time control, and operational efficiency.

Why Choose Flextech for Industrial Automation Solutions?

Flextech stands out as a trusted partner for businesses seeking advanced automation solutions. Here’s why companies choose Flextech:

- Comprehensive Expertise: Flextech has extensive experience in industrial automation, including PLC programming, PID control, IIoT integration, and smart factory solutions.

- Tailored Solutions: Every project is customized to meet specific operational needs, ensuring maximum efficiency, reliability, and scalability.

- Cutting-Edge Technology: Flextech leverages the latest automation technologies, including AI, IIoT, and modern control systems, to optimize processes and reduce operational costs.

- Strong Technical Support: From initial design to implementation and maintenance, Flextech provides continuous support and training to ensure smooth operation.

- Proven Track Record: Numerous satisfied clients across manufacturing, energy, automotive, and logistics sectors trust Flextech for delivering high-quality, reliable automation solutions.