Supervisory Control and Data Acquisition (SCADA) refers to an integrated control architecture that enables centralized monitoring, automation, and data collection across industrial and warehouse environments. Essentially, SCADA bridges the communication gap between machines and operators by combining both hardware and software elements to control and optimize complex processes.

In warehouse and logistics automation, SCADA ensures smooth operations, reduces manual workloads, and supports real-time decision-making. It gives supervisors the ability to visualize ongoing processes, monitor performance trends, and control multiple systems from one centralized interface.

Beyond warehousing, SCADA is widely applied in industries like manufacturing, power generation, oil and gas, and water treatment, where consistent supervision and efficiency are critical.

What Are the Core Components That Make Up a SCADA System?

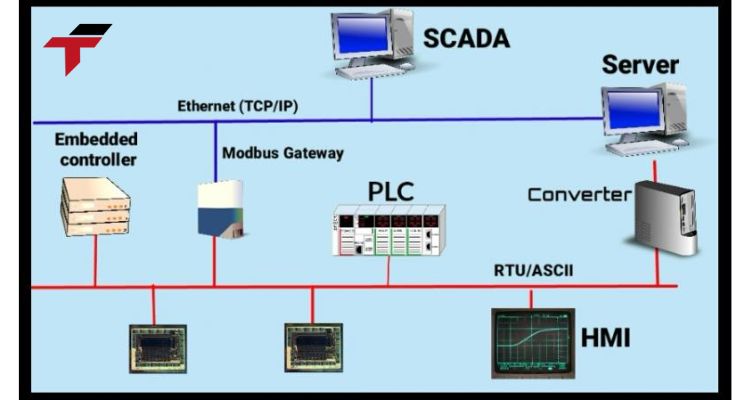

A complete SCADA system consists of several interrelated components that handle data acquisition, control, and visualization. The key elements include:

- Human–Machine Interface (HMI): A graphical interface that lets operators visualize system performance, monitor real-time data, and execute control commands.

- Supervisory System (SCADA Software): The central hub that collects, processes, and stores data from the field, while issuing commands to various equipment.

Remote Terminal Unit (RTU): A data collection device that transmits sensor data to the SCADA system and relays control signals to actuators. - Programmable Logic Controller (PLC): Industrial computers responsible for executing logic-based control at high speed, often complementing RTUs.

- Communication Network: The wired or wireless infrastructure connecting all SCADA elements for data exchange.

- Sensors and Actuators: Field instruments that detect parameters (temperature, pressure, flow) and perform physical actions (open valve, start motor, etc.).

What Are the Core Components That Make Up a SCADA System?

How Does a SCADA System Operate in Practice?

SCADA’s operation follows a structured and continuous process involving several key stages:

- Data Acquisition: Sensors detect real-time variables such as temperature, speed, or voltage.

- Transmission: RTUs or PLCs send this data over the communication network to the central SCADA software.

- Processing and Visualization: SCADA software interprets and organizes the data, which is then displayed on HMI panels for operator review.

- Control Execution: Operators—or automated logic—initiate responses such as adjusting motor speed or stopping equipment.

- Feedback and Optimization: The system continuously monitors outcomes, ensuring stable operation and enabling predictive maintenance.

This closed-loop feedback system provides real-time insight, minimizes downtime, and enhances both safety and productivity.

What Are the Key Features and Functions That SCADA Provides?

Modern SCADA systems come with a comprehensive suite of functionalities designed to simplify and optimize industrial management:

- Real-Time Monitoring: Constant visibility into machine and system status.

- Data Logging and Trending: Historical data collection for reporting, compliance, and performance analysis.

- Alarming and Notifications: Automated alerts for abnormal readings or critical system faults.

- Remote Control: Operators can control processes from any location without direct physical access.

- Automation: Streamlined operation of repetitive or time-sensitive tasks.

System Integration: Seamless connectivity with MES (Manufacturing Execution System), ERP (Enterprise Resource Planning), and WMS (Warehouse Management System).

What Are the Key Features and Functions That SCADA Provides?

Where Can SCADA Systems Be Applied Across Industries?

The versatility of SCADA allows it to be deployed in a wide variety of sectors and environments, such as:

- Warehouse Automation: Supervising conveyors, AGVs, lifters, and automated storage systems.

- Manufacturing Plants: Tracking production lines and ensuring consistent product quality.

- Utilities: Controlling water treatment facilities, power grids, and HVAC systems.

- Oil and Gas: Managing pipeline pressures and flow systems remotely.

- Transportation: Regulating railway signaling and smart traffic systems.

In modern warehouse operations, SCADA acts as the central intelligence layer — synchronizing conveyors, robots, and AS/RS units to ensure cohesive operation across all automated systems.

How Are SCADA Systems Structured in Different Operational Levels?

SCADA architecture is typically organized into multiple hierarchical levels, each responsible for specific functions:

- Level 0 – Field Level: Involves all the physical devices such as sensors, valves, and actuators that interact directly with machinery or the environment.

- Level 1 – Control Level: Comprises PLCs and RTUs that execute real-time control logic, responding immediately to inputs from field devices.

- Level 2 – Monitoring Level: Encompasses SCADA software and HMI interfaces, where operators supervise processes, visualize data, and handle alarms.

- Level 3 – Production Level: Integrates Manufacturing Execution Systems (MES) that coordinate production workflows, scheduling, and inventory management, linking SCADA with higher enterprise systems.

How Are SCADA Systems Structured in Different Operational Levels?

How Do SCADA and PLC Differ from Each Other?

Although SCADA and PLC are closely linked in industrial automation, they perform distinct functions:

| Feature | SCADA | PLC |

| Interface | Graphical dashboards and HMI displays | Ladder logic programming interface |

| Function | System-wide supervision and data analysis | Real-time control of individual machines |

| Scope | Monitors and manages large-scale processes | Executes direct control commands |

| Flexibility | Highly adaptable for visualization and reporting | Fixed, logic-based operations |

| Typical Use | Overseeing warehouse or plant operations | Controlling motors, conveyors, lifters, etc. |

Together, PLCs act as the hands of the automation system – executing commands and controlling machinery while SCADA functions as the brain, monitoring and optimizing performance in real time.